-

صفحة رئيسية > المنتجات >

modern feeder ore crusher

2022-04-13T09:04:41+00:00

Feedhopper level estimation and control in cone crushers

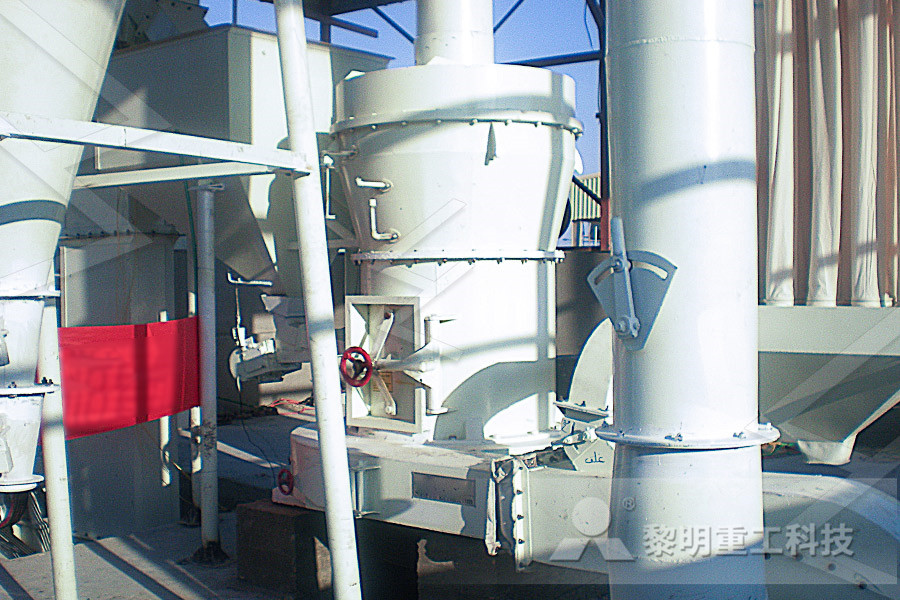

2017年8月15日 Abstract This paper describes a novel feedhopper level estimation and control scheme for addressing the known problem of unreliable and occasionally 2020年4月15日 Feeder breakers offers flightbar feeders, flightlessfeeders, and feeder breakers for truckfed, loaderfed, and dozerfed applications The Crushing Systems The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiationDuring the crushing process, the threestage closedcircuit Manganese ore crushing equipment processing technology

Mining feeder,Feeder machine,Ore feeder,Feeder

2022年8月29日 Mining Feeder The mineral feeding machine produces centrifugal force depending on the rotation of the eccentric block in the vibrating device to make the sieve and vibrating device move in circle or Crushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in mining Crushers All crusher types for your reduction needs Feederbreakers and reclaim feeders; Apron feeders and belt feeders; Remote control technology to control crushing units; Vibrating screens and scalpers; Hammer mills; Ball Crushers, breakers and grinding mills for the mining industry

Ore Feeder Machine Price, 2023 Ore Feeder Machine

Ore Feeder Machine Price Select 2023 high quality Ore Feeder Machine Price products in best price from certified Chinese Plastic Machine manufacturers, Feeder Machine Chain Feeder: successful in cement aggregates, recycling, coal handling applications Used as material transfer unit and discharge conveyorCHAIN FEEDER HCF China Feeding Equipment Supplier, Crusher Equipment, Grinding Equipment Manufacturers/ Suppliers Jiangxi Hengchang Mining Machinery Manufacturing Co, Ltd 30tph Ore Plant Mining Machinery Jaw China Feeding Equipment Manufacturer, Crusher

China Ore Crusher, Ore Crusher Manufacturers, Suppliers,

China Ore Crusher manufacturers Select 2023 high quality Ore Crusher products in best price from certified Chinese Crushing Machine, Mineral Screen suppliers, wholesalers 2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can Selecting the right crusher for your operations2023年11月2日 5 52 Gyratory crusher : A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel SIZE REDUCTION BY CRUSHING METHODS By

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日 Prediction of crusher performance has been focused on, since crushing is a vital process for both industries An example of a crushing plant is shown in Figure 1 In the first step, feeder and Contribute to yunan88/crusher development by creating an account on GitHubcrusher/ gravel vibrating feeder crusher mills cone crusher There are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of Crushers All crusher types for your reduction needs

Selftuning control of an ore crusher ScienceDirect

1976年1月1日 The ore enters the crushing line on an electromechanical feeder A conveyor belt takes it to the first screen, where lumps which already have the desired dimension are separated The rest of the ore proceeds to the crusher Some part of the ore leaving the crusher consists of lumps with a dimension greater than 25 ram2016年2月28日 Crushing Equipment Selection In open pit quarry operations the loading of the blasted rock for transportation to the primary crusher house involves either powershovels Any size of primary crusher may be used for handloaded rock; it all depends upon how much secondary shooting, and hand sledging, the operator feels he can afford So Crushing Equipment Selection 911 Metallurgist2021年12月6日 Crushed ore Gravity screen Intensive leach Carboninleach Carbon fines Primary cyclones Secondary cyclones Ball mill discharge pump box Apron feeder Apron feeders Preleech Gravity thickener separators Gravity tailings pump box Induction furnace Kiln Stacker SAG mill To waste dump Vibrating feeder Pebble crusher Pebble crusher Mining Mineral Processing Schenck Process

Crushing Plant Design and Layout Considerations 911

2016年2月24日 crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climatic2022年12月26日 To calculate the feed rate, you will need to use the following formula: Feed rate (in cubic feet per hour or cubic meters per hour) = (belt speed (in feet per minute or meters per minute) * belt how to calculate belt feeder LinkedIn2016年2月28日 A crusher’ surge pocket, sometimes called a “rock box“, is found directly below the primary gyratory crusher It provides limited storage, normally about two truckloads, to enable smooth feeding of crushed Crusher Surge Pocket AKA "Rock Box" 911

Crushing

inpit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services Through the industry's strongest building blocks of team, technology and services, is able to deliver successful IPCC operations combines our 2021年3月25日 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, What Type of Crusher Is Best for Primary 2016年5月5日 A Chain Feeder was installed for control of the coarse ore to the crusher Crushed ore conveyor is enclosed in a conveyor¬way for weather protection Fine ore bin is housed within the mill building to prevent freezing An inclined belt feeder with variable speed drive gains elevation to grinding mill Feeder was designed with sloping hopper to Design Flotation Plant 911 Metallurgist

Practical considerations on improved feeding

2016年1月12日 replacement crusher is being planned, careful consideration is required to the design of the feeding arrangement zMaterial normally arrives in a stream, from a conveyor, feeder or chute—the need is for even full width distribution with no segregation zHeight can be an ally when available and employed to constrain2023年2月13日 Other auxiliary equipment for iron ore processing include vibrating feeder, belt conveyor, and vibrating screen These equipment work together to form a complete iron ore processing system Like what are the equipment in iron ore crusher? LinkedIn2019年7月8日 Normally, the optimal speed an apron feeder is 005 – 040 m/second (10–80 fpm) If the ores are nonabrasive, the speed can increase to above 030 m/second because there will be less wear Higher speeds would hurt an operation If your speed is too high, you run the risk of accelerated wear of components Energy efficiency decreases Feeding the facts: Apron feeder basics

Apron feeders: the material handling workhorses

2019年10月3日 It is not unusual for 1,500 mm of material to be extracted if a 3,000 mm wide feeder is used Material of minus300 mm from crusher ore stockpiles or storage/blending bins is typically extracted with apron feeders to feed secondary crushers What information is required when sizing an apron feeder?2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap How it Works: Crushers, Grinding Mills and Pulverizers2019年6月28日 The Ross Chain Feeder serves the purpose of slowing the violent rush of dense heavy rock through the feeder system all the way in to the crusher This will provide significant wear protection on the feeder system due to drastically reducing the impact velocity of the ore with the feeder apparatusCrushers QueensMineDesignWiki

Crushing Plant Flowsheet DesignLayout 911 Metallurgist

2016年3月10日 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone Vanessa Zhou May 5, 2019, 8:42 am Feeder breakers and feeder/sizers are both used as primary crushing options in runofmine (ROM) coal crushing operations, however there are a number of reasons Why have feeder breakers become the ROM crusher of Feederbreakers and reclaim feeders; Apron feeders and belt feeders; Remote control technology to control crushing units; Vibrating screens and scalpers; Selecting the correct crusher depends on ore characteristics such as abrasiveness, fragility, softness or stickiness, and the desired outcome The crushing process can include primary Crushers, breakers and grinding mills for the mining industry

Crusher an overview ScienceDirect Topics

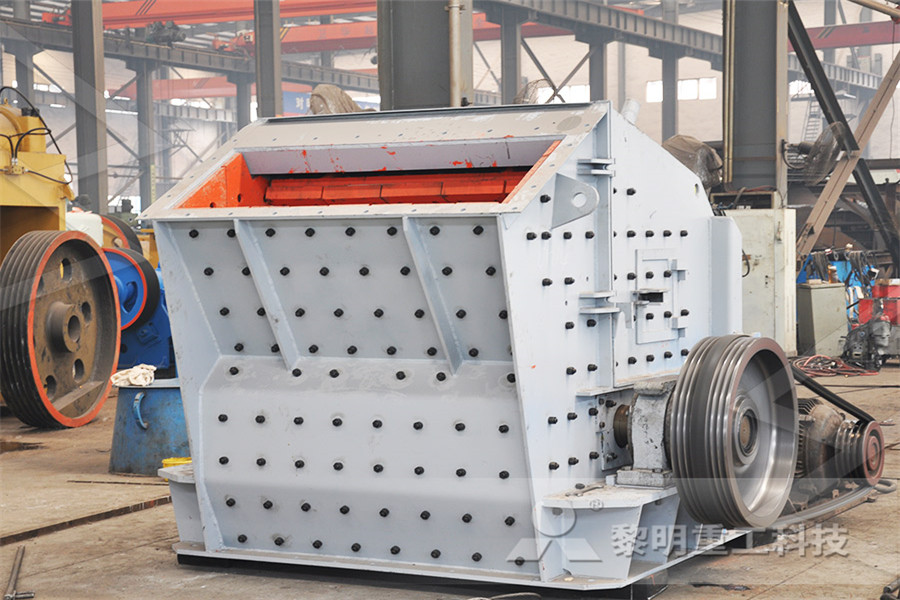

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Modern Feeder Ore Crusher jungheinrichpolska Modern Feeder Ore Crusher Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce modern feeder ore crusherThe company explained: "This unique jawgyratory crusher is a modern machine based on the proven BK 6375 design thyssenkrupp has developed a new, patented, spider to give the opportunity to feed the crusher from both sides – the "double mouth" jaw configuration, thus removing the need for a primary crusher feed (buffer) hopper and primary Modern Feeder Ore Crusher

Wobbler feeders

Versatile applications For increased operational flexibility in your mining operations, wobbler feeders can be used for mineral processing, bulk loading and unloading terminals, as well as for inpit and underground operations They operate with low horsepower and headroom requirements, and without vibration, noise or transmitted stresses CHAIN FEEDER HCF WITH REPLACEABLE WEAR PARTS Chain Conveyor with replaceable wear parts (also used in Horizontal Impact Crusher HHI) Type Nominal outer width [mm] Nominal inner width [mm] HCF 1500 1840CHAIN FEEDER HCF The Double Roll Crusher DRC withstands the toughest mining conditions while delivering consistent, highperformance crushing thanks to its working principle and several key features In the DRC the feed material is fed by a continuous feed arrangement into the middle of the machine between both rolls The rolls are operating with 5 m/s Double Roll Crusher DRC

GitHub

mining feeder line vibrating feeder match with crushersvibrating feeder supplier for minerals processing industry Vibrating Feeder for Mining India,Vibrating Feeder We can so2021年1月26日 Apron Feeders are a popular material handling choice for a variety of applications, including aggregates, coal and other mining ore, and scrap/recycle material, because they deliver material at a constant McLanahan Everything You Need to Know about The process of gold ore processing and production mainly includes three processes: crushing, grinding and beneficiation In the crushing process, the threestage closedcircuit crushing is more modern and suitable for highhardness gold ore crushing, which can complete the work of ore crushing and partial dissociation, thereby improving the Gold Ore Processing Solution Eastman Rock Crusher

mill/ roller feeder ore processing alogmd at main

Contribute to crush2022/mill development by creating an account on GitHub13 Jan 2023; Manganese ore crushing process The crushing of manganese ore is generally a threestage crushing process: large pieces of manganese ore are evenly sent to the jaw crusher or coarse crushing mobile station through the silo by the vibration feeder; The coarse crushed manganese ore is screened by vibrating screen and sent to the single manganese ore with what crushing equipment processing?2023年11月5日 The vibrating feeder is widely used in the crushing and screening process of mining and gravel production lines to feed materials continuously and evenly Application: Feeding sand/aggregate/ore to a crusher or other equipment; typically used for material conveying in the aggregate, mining, quarry industries, etc How It WorksVibrating Feeder Mineral Processing

Crushing Screening Plant 911 Metallurgist

2016年7月12日 The feeder is driven by a 5hp motor through a bronze worm reducer, with a sprocket chaingear and pinion arrangement a 5½ft Symons cone crusher is fed with ore of 3½ to 4 in maximum size which has passed over a vibrating screen having 018 by 09in openings The Symons produces 100 tons an hour of ½in material for further Quality feed machine, feeder, crusher feeder find quality feeder, Mining Feeder feeder from Luoyang Zhongde Heavy Industries Co, Ltd of China Suppliers GZD series grizzly stone ore vibratory jaw crusher feeder price for sand making plant;feed machine, feeder, crusher feeder of feeder from China According to the functions or types of Feeder For Crusher Price, Feeder For Crusher Price can be classified into many types Be honest about your volume and choose the Feeder ForMadeinChina

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame, and tramp release mechanism (mechanically or hydraulically actuated) Cone Crusher Components Top Shell Spider Cap Assembly The feed is fed by conveyors to a feed All can be equipped with gasoline or electric power Marcy ® Lab Cone Crusher is ideal for reducing aggregates and mineral ores The Marcy ® GYRoll 6in (152mm) or 10in (254mm) Lab Cone Crushers have 300lb per hour (136kg) or 600lb per hour (272kg) throughput capacity The throughput rate is dependent upon the material crushed; with coarser Aggregate Crushers, for Rock, Ore Minerals Gilson Co2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can Selecting the right crusher for your operations

SIZE REDUCTION BY CRUSHING METHODS By

2023年11月2日 5 52 Gyratory crusher : A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel 2015年5月13日 Prediction of crusher performance has been focused on, since crushing is a vital process for both industries An example of a crushing plant is shown in Figure 1 In the first step, feeder and (PDF) Cone Crusher Performance ResearchGateContribute to yunan88/crusher development by creating an account on GitHubcrusher/ gravel vibrating feeder crusher mills cone crusher

Crushers All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of 1976年1月1日 The ore enters the crushing line on an electromechanical feeder A conveyor belt takes it to the first screen, where lumps which already have the desired dimension are separated The rest of the ore proceeds to the crusher Some part of the ore leaving the crusher consists of lumps with a dimension greater than 25 ramSelftuning control of an ore crusher ScienceDirect2016年2月28日 Crushing Equipment Selection In open pit quarry operations the loading of the blasted rock for transportation to the primary crusher house involves either powershovels Any size of primary crusher may be used for handloaded rock; it all depends upon how much secondary shooting, and hand sledging, the operator feels he can afford So Crushing Equipment Selection 911 Metallurgist

Mining Mineral Processing Schenck Process

2021年12月6日 Crushed ore Gravity screen Intensive leach Carboninleach Carbon fines Primary cyclones Secondary cyclones Ball mill discharge pump box Apron feeder Apron feeders Preleech Gravity thickener separators Gravity tailings pump box Induction furnace Kiln Stacker SAG mill To waste dump Vibrating feeder Pebble crusher Pebble crusher 2016年2月24日 crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticCrushing Plant Design and Layout Considerations 911 2022年12月26日 To calculate the feed rate, you will need to use the following formula: Feed rate (in cubic feet per hour or cubic meters per hour) = (belt speed (in feet per minute or meters per minute) * belt how to calculate belt feeder LinkedIn

modern feeder ore crusher

Feedhopper level estimation and control in cone crushers 2017年8月15日 Abstract This paper describes a novel feedhopper level estimation and control scheme for a