-

صفحة رئيسية > المنتجات >

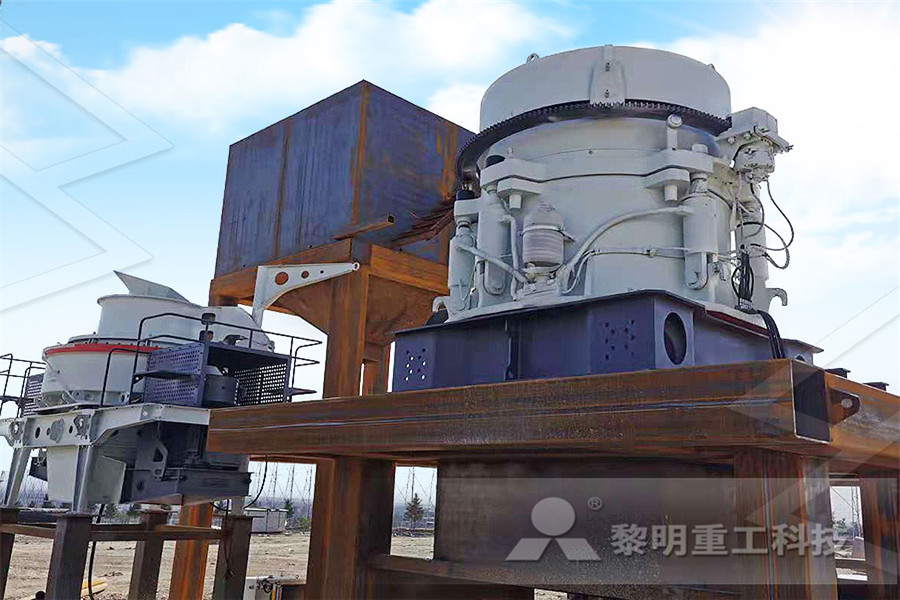

hydraulic station for vertical roller mill

2021-05-07T10:05:55+00:00

Hydraulic station北方重工

MLS vertical roller mill Roller Press MTN drum roller mill Tube Mill (Dry type) Bulk Material Handling Machinery Belt conveyor Tube belt conveyor Hydraulic station en Full Static 2023年10月16日 The power system of automatic control: Oil terminal and hydraulic pressure station system startup conditions meet can start roller mill power systems Design and Realization Of Roller Mill Control System2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) Roller Mill Springer

The important role of vertical roller mills in the cement industry

GRMK vertical cement mill has the advantages of compact structure and small volume It mainly includes high efficiency separator, grinding rollers, grinding table, hydraulic 2023年3月22日 China Advanced Hydraulic Station Vertical Roller Mill Stable Performance, Find details about China Vertical Roller Mill from Advanced Hydraulic Station Vertical China Advanced Hydraulic Station Vertical Roller Mill Stable Hydraulic station type:D700 18 Disc liner:*T,HRC60 19 Roller cover:*20Mo2GT,HRC60 20 Middle cover:Q235A 21 Lower cover:Q235A 22 Roller shaft:45Cr 23 Roller HRM1700 vertical millProduct

Full article: Reliability assessment of the vertical roller mill

Hence in this paper, through deploying the hydraulic monitoring points in the hydraulic loading system, monitoring the change of hydraulic in the system and establishing the 2020年8月12日 PDF This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, Find, read and cite all theAn investigation of performance characteristics 2022年4月4日 remove the roller unit The quadropol differs from other VRM systems due to the arrangement of the roller units outside of the mill housing Since the hydraulic systems of each roller unit can Table 1: QMR² performance values of quadropol cement mills during operation, Cementos Progreso, Guatemala Design parameter Nominal Operation QMR2 VERTICAL ROLLER MILLS A holistic VRM approach

Design and Realization Of Roller Mill Control System

2023年10月16日 438 QianHong Wang et al / Physics Procedia 33 ( 2012 ) 437 – 443 Among the rest, stable operation of the vertical mill vertical means that to ensure the material layer thickness of the disc 2012年12月31日 Abstract and Figures a Distributed Control System (DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT The results demonstrate the (PDF) Design and Realization Of Roller Mill 2014年11月2日 The raw material feeding and recirculation system is preferably placed at the left side of the ATOX mill, seen from the mill motor Lubrication stations for main gear,hydraulics and roller lubrication areplaced with the pump station insidethe structure, below the cyclonesThe layout is furthermore prepared for easy access to machinery and Atox Raw Mill [PDF Document]

(PDF) Increase productivity of vertical roller mill

2021年1月29日 FlyAsh Blaine: Increase fly Ash Blaine from 290 to 320 Flyash is a major supply for any cement plant now a days because every producer wants to produce more PPC than OPC due to profitability 2023年10月27日 A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for Energysaving and Efficient Vertical Roller Mill Fote MachineryFor the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials[12] It has advantages like low power consumption, process simplifications and Speed, Mill Inlet Outlet Temp, Hydraulic Pressure, equipments, control logic, PID tuning, breakdowns etc Some parameters like excess vibration Indicate Contributions from Several Radial

How to choose between ball mill and vertical roller mill?

2022年6月24日 4 Grinding process In the ball mill, the material is mainly crushed by impact and friction In the vertical grinding mill, the material is mainly extrusion, and grinding is the auxiliary The residence time of the material in the vertical mill is 23 minutes, while in the ball mill it takes 1520 minutes2020年8月13日 cylinders, hydraulic accumulators and hydraulic unit, and the table driven by electrical motor through high efficiency vertical planetary gear reducer At the same time, raw material is dried by hot gas induced through the louver ring installed at outer side of the table Construction This Machine is a vertical type roller mill which performsVERTICAL ROLLER MILLS AMCLFRA Roller Team Gamme Roller Team2 3 CHASSIS AUTOROLLER 264 P AUTOROLLER 264 TL AUTOROLLER 265 P AUTOROLLER 265 TL AUTOROLLER 266 P AUTOROLLER 266 TL AUTOROLLER 275 Documents MANUFACTURING HEAVY EQUIPEMENTS R C DAS We are supplying Atox Mill Roller Assembly to M/S (PDF) RAW MILL VERTICAL ROLLER MILLpdf

Hydraulic station北方重工

MLS vertical roller mill Roller Press MTN drum roller mill Tube Mill (Dry type) Bulk Material Handling Machinery Belt conveyor Tube belt conveyor Hydraulic station en Full Static pressure oil station Medium Speed Coal Mill Hydraulic System 2021年4月12日 Uploaded by ManpreetSaran AIenhanced title and description The vertical roller mill MLS3424A is used for grinding cement raw meal and the raw material for building, chemical and ceramic Raw Mill Vertical Roller Mill PDF PDF ScrewMLS vertical roller mill Roller Press MTN drum roller mill Tube Mill (Dry type) Bulk Material Handling Machinery Belt conveyor Tube belt conveyor Hydraulic station en lubrication station Lubrication station en Electrical Control Equipment Electrical Control SystemPower Plant Equipment北方重工 NHI

vertical mill rocker arm and separetor LinkedIn

2016年12月15日 Vertical mill pressure device is to provide the pressure roller milling parts, which consists of highpressure filling stations, hydraulic cylinder rod, accumulator etc, able to exert enough 2021年1月28日 The vertical roller mill is the appropriate equipment for grinding and drying of wet materials Force F, applies for rocker arm type mills, where the force from the hydraulic cylinder has to be converted to F2 with the lever arm ratio Table speed n: is a function of Dy for a constant centrifugal force of the material on theHolderbank Cement engineering book ArchiveMPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, China MPS 5000 B mill for raw material grinding, Turkey Tracim, Turkey MPS 5300 B mill for cement raw material grinding, CDI Hail Cement, Saudi Arabia Gebr Pfeiffer SECoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

北方重工 NHI

Among them, the "Shenyang Heavy"brand raw material mill is "China famous brand" product and we have atotal sale of more than 1000 sets The 5000t/d capacity MLS4531 raw material vertical mill NHI independently developed and manufactured is the largest NSPcement production line host equipment in China now2023年8月31日 6 Under the function of accessory hydraulic cylinder, the roller can be removed outside of mill for inspection and repair easily 7 There has device around the grinding disc to prevent disc base wearing, adjust the air speed of air ring and the material thickness, to guarantee 7 the vertical mill' capacity and operation economical 8VERTICAL ROLLER MILLZK Ball MillRotary KilnGrinding 2008年3月13日 Raw Mill Vertical Roller Mill PDF Free download as PDF File (pdf), Text File (txt) or read online for free ×20Mpa Oil cylinder working pressure 20MPa Motor of hydraulic station: Power: 75kW Speed: 1450rpm Power of electric Raw Mill Vertical Roller Mill PDF PDF Mill (Grinding)

Research on vibration characteristics of mill rolls based on

2021年4月1日 Considering the nonlinear stiffness constraint action from the hydraulic cylinder in the fourhigh rolling mill process, the vertical vibration dynamic model with two degrees of freedom is established The nonlinear vertical vibration equation of roll system contained the nonlinear stiffness of the hydraulic cylinder is established on the basis of 2019年6月29日 OK mill Ball mill OK mill Ball mill OK mill Ball mill 3 days 155 145 225 220 115 110 7 days 255 245 275 260 195 190 28 days 430 420 350 330 425 425 *50/50 clinker and slag mixture Portland cement Slag* RollerTable Table Roller Without hardfacing1 1 65 With hardfacing05 3005 25 *50/50 clinker and slag mixtureOK vertical roller mill Environmental2021年3月13日 A vertical roller mill is equipment used in both raw material cement grinding hydraulic station pressure 17 pump#1,2 HSMS PUMP 101 Reducer lubrication station bypass cleaning pump 101 Water spray pump motor Raw mill classifier water spray pump motor#1,2 037 Raw mill cyclone rotary motor#1,2,3,4 55 Raw mill system fan Loesche Roller Grinding Mill PDF Gases Mechanical

(PDF) Performance Evaluation of Vertical Roller

2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the During the sintering operation, iron ore powder with different components and sizes, solvent, fuel, etc are sintered into blocks, and harmful impurities such as sulfur, phosphorus, arsenic, etc contained in the ore powder are partially eliminated 2Model and Specification Specification: SD180~SD660 Capacity (t/h): 490~1550 3Product Straightline sintering machine北方重工Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulatorsVertical roller mill with improved hydropneumatic loading system

Steckel Mill北方重工

Steckel mill is generally divided into small mill, medium mill and large mill according to the product specification, that is, defined by the working length of the work roll body of the mill The steckel mill developed by NHI is used to center the slab through the entrance centering device, and then after passing through the reversible mill 2020年3月6日 2 Grinding roller is used to grind and crush materials 3 The grinding table is fixed on the output shaft of the reducer It is the place where the grinding rollers grind materials 4 The The important role of vertical roller mills in the cement industryTEL:+86 24 ;+86 24 Email: Strip Steel Mill Steckel Mill Profile rolling Wheel Hub Rolling mill Magnesium alloy cold mill Magnesium alloy hot millRolling mill北方重工 NHI

Factors affect the operation and running of vertical roller mill

2021年11月5日 The grinding force of vertical roller mill comes from the dead weight of grinding roller and the pressure of hydraulic station, and the hydraulic tension device is the main source of grinding force The working pressure of the grinding roller needs to be reasonably set according to the feed volume, material layer thickness, product fineness 2019年10月11日 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM) For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted This is considered a resistance to change Vertical roller mills: The new leader in grinding technology2022年1月2日 1 Grinding rollers can be turned out of mill by a hydraulic device, it is convenient to replace roller tyre, and the overhaul space of VRM is big and easy overhaul working 2 The rollers tyre can be used with another side to prolong the useful life of wear resisting material, 3Operation Manual: HRM1700M Vertical Roller Coal Mill

Coal Mine Machine北方重工

Coal Mine Machine NHI has open pit coal mine machinery and underground coal mine machinery, mainly include excavating machinery and coal mining machinery, including cantilever excavator and electric haulage coal shearer 1100WD Series AC electric haulage shearer 710WD Series AC electric haulage shearer EBZ106A Boring Machine2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING 1 Scope of Application The spiral vertical mill is mainly used in the crushing and grinding of metal ores, the crushing and deep processing of nonmetallic ores, the comprehensive utilization of lowgrade minerals, the extraction of useful elements from tailings and other mining industries, powder metallurgy, mechanical alloying, metallurgical raw material 北方重工 chinasz

Vertical roller mill with improved hydropneumatic loading system

Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulators2021年8月3日 Fig3 The monitor screen of oil station in roller mill In raw cement freestanding roller grinding oil terminal process, when through the mill chamber wind path to control temperature and pressure to meet requirements, that is ready to launch lubrication station and hydraulic pressure station Start each station in before, should guarantee theDesign and Realization Of Roller Mill Control System2023年6月8日 Here are some considerations: Energy Efficiency: Vertical roller mills (VRM) generally have a higher energy efficiency compared to ball mills This is because of the higher grinding efficiency and Which is better cement vertical roller mill or ball mill?

Vertical roller mill hydraulic system Google Patents

The invention relates to a vertical roller mill hydraulic system, which comprises a plurality of grinding roll clamping hydraulic cylinders, a plurality of accumulator groups, a hydraulic station and connecting pipelines among the grinding roll clamping hydraulic cylinders, the accumulator groups and the hydraulic station, wherein the hydraulic station comprises an 2021年1月1日 Now a days Cement plants are producing 75–80% PPC 20–25% OPC due to high market demand of PPC Production of PPC is cheaper and it's market rate is also lower than OPC by nearly 25 rupees per bag, so general consumer are attracted towards PPC cement Cement companies also want to produce more and more PPC gradeReview on vertical roller mill in cement industry its 2023年4月9日 Annual Revenue: USD Employees: 100~200 Year Established: 2000 Manufacturer, ExporterVertical Roller Mill, Vertical Roller Mill direct from Guangxi

VERTICAL ROLLER MILLS A holistic VRM approach

2022年4月4日 remove the roller unit The quadropol differs from other VRM systems due to the arrangement of the roller units outside of the mill housing Since the hydraulic systems of each roller unit can Table 1: QMR² performance values of quadropol cement mills during operation, Cementos Progreso, Guatemala Design parameter Nominal Operation QMR2 2023年10月16日 438 QianHong Wang et al / Physics Procedia 33 ( 2012 ) 437 – 443 Among the rest, stable operation of the vertical mill vertical means that to ensure the material layer thickness of the disc Design and Realization Of Roller Mill Control System2012年12月31日 Abstract and Figures a Distributed Control System (DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT The results demonstrate the (PDF) Design and Realization Of Roller Mill

Atox Raw Mill [PDF Document]

2014年11月2日 The raw material feeding and recirculation system is preferably placed at the left side of the ATOX mill, seen from the mill motor Lubrication stations for main gear,hydraulics and roller lubrication areplaced with the pump station insidethe structure, below the cyclonesThe layout is furthermore prepared for easy access to machinery and 2021年1月29日 FlyAsh Blaine: Increase fly Ash Blaine from 290 to 320 Flyash is a major supply for any cement plant now a days because every producer wants to produce more PPC than OPC due to profitability (PDF) Increase productivity of vertical roller mill2023年10月27日 A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for Energysaving and Efficient Vertical Roller Mill Fote Machinery

Indicate Contributions from Several Radial

For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials[12] It has advantages like low power consumption, process simplifications and Speed, Mill Inlet Outlet Temp, Hydraulic Pressure, equipments, control logic, PID tuning, breakdowns etc Some parameters like excess vibration 2022年6月24日 4 Grinding process In the ball mill, the material is mainly crushed by impact and friction In the vertical grinding mill, the material is mainly extrusion, and grinding is the auxiliary The residence time of the material in the vertical mill is 23 minutes, while in the ball mill it takes 1520 minutesHow to choose between ball mill and vertical roller mill?2020年8月13日 cylinders, hydraulic accumulators and hydraulic unit, and the table driven by electrical motor through high efficiency vertical planetary gear reducer At the same time, raw material is dried by hot gas induced through the louver ring installed at outer side of the table Construction This Machine is a vertical type roller mill which performsVERTICAL ROLLER MILLS AMCL

(PDF) RAW MILL VERTICAL ROLLER MILLpdf

FRA Roller Team Gamme Roller Team2 3 CHASSIS AUTOROLLER 264 P AUTOROLLER 264 TL AUTOROLLER 265 P AUTOROLLER 265 TL AUTOROLLER 266 P AUTOROLLER 266 TL AUTOROLLER 275 Documents MANUFACTURING HEAVY EQUIPEMENTS R C DAS We are supplying Atox Mill Roller Assembly to M/S

hydraulic station for vertical roller mill

Hydraulic station北方重工 MLS vertical roller mill Roller Press MTN drum roller mill Tube Mill (Dry type) Bulk Material Handling Machinery Belt conveyor Tube belt