-

صفحة رئيسية > المنتجات >

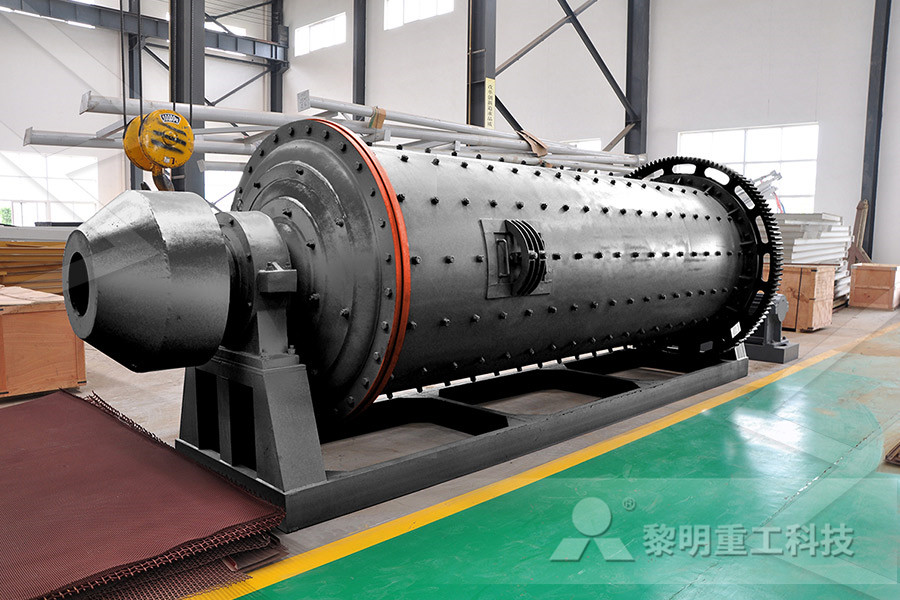

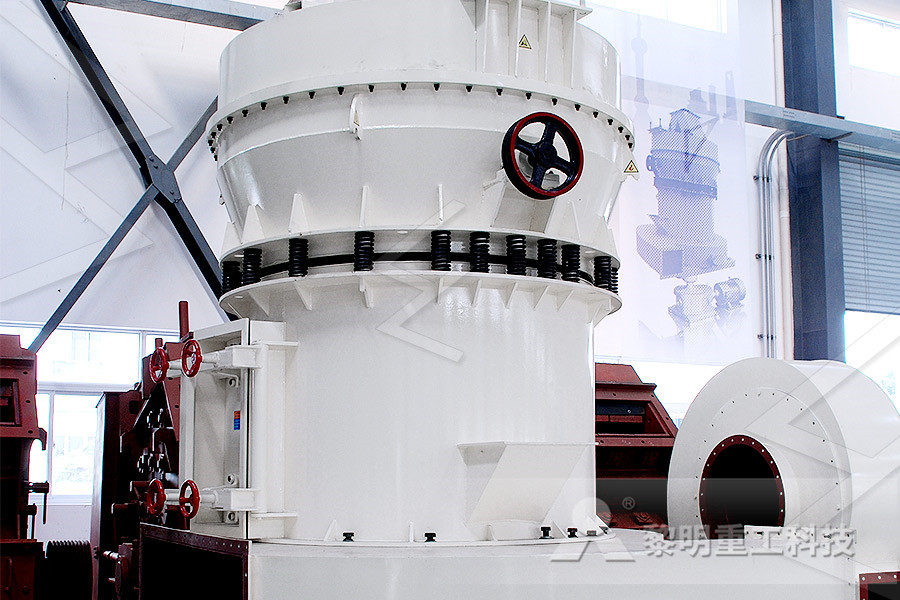

effect of ball size in ball mill

2023-12-05T09:12:07+00:00

Effect of ball size and powder loading on the milling efficiency

2013年12月1日 Here we report that there exists an optimal ball size for efficient milling at a given rotation speed, based on a laboratoryscale wet ball mill Also, the effect of powder 2020年7月2日 Read this article A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, Effects of Ball Size Distribution and Mill Speed and Their Interactions 2021年7月31日 24 Effect of ball size 29 241 Empirical approaches 29 242 Probabilistic approaches 33 25 Abnormal breakage 36 26 Effect of ball mixture 37 261 Ball size EFFECT OF BALL SIZE DISTRIBUTION ON MILLING

Minerals Free FullText Effects of Ball Size on

2019年10月31日 In this study, we investigate the effect of the ball size in a highenergy ball mill on the comminution rate and particle size reduction 2009年6月1日 Ball size is a critical parameter influencing the performance of a ball mill, particularly for multicompartment ball mills used in cement industry Studies for selection The effect of ball size on breakage rate parameter in a pilot 2018年2月1日 It was also observed from the experimental results that in order to increase the milling efficiency of a ball mill, towards optimum production of material in the desired size class, there is(PDF) Effect of ball and feed particle size

Ball size distribution for the maximum production of a

2015年11月1日 In this research, ball size distribution which is a function of makeup ball sizes was investigated to optimise the milling stage of a grinding circuit in order to 1976年5月1日 Abstract The specific rates of breakage of particles in a tumbling ball mill are described by the equation Si = axαi ( Q ( z ), where Q ( z) is the probability function The effect of ball size on mill performance ScienceDirect2013年12月1日 The variation of ball size in a planetary ball mill (PBM) was studied in terms of its effect on the specific impact energy of balls as a result of ball to ball and ball to vial Effect of ball size and powder loading on the milling

Predicting the effect of operating and design variables on

2013年4月1日 The predicted influence of particle and ball size, mill filling, speed and frequency was in general qualitative agreement with evidence from the literature, as well from predictions using the traditional scaleup methods of Herbst and Fuerstenau (1980) and Austin et al (1984) The effect of ball size on the breakage parameter in a pilot 2019年5月16日 The results of particle size analyzer are shown in table 1 It can be seen that the increase in diameter of the steel ball does not have any certain correlation to the decrease of the particle size The smallest particle having average size of 2738 nm is produced by the ¼ inch ball diameter The sizes of 4901PAPER OPEN ACCESS 7KHHIIHFWRIWKHEDOOVL 2020年1月29日 An investigation was conducted to determine the effect of the ball diameter sizes on milling operation A laboratory size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively Quartz was the material used to perform the experiment and was arranged into 3 monosizes namely 8 mm +56 mm, 4 mm +28 The Effect of Ball Size Diameter on Milling Performance

Ball size distribution for the maximum production of a

2015年11月1日 Abstract Ball size distribution is commonly used to optimise and control the quality of the mill product A simulation model combining milling circuit and ball size distribution was used to determine the best makeup ball charge The objective function was to find the ball mix that guarantees maximum production of the floatable size range (ie 2023年3月22日 The size of the ball in a ball mill has a significant effect on the mill’s performance, including the production rate, material grindability, and power consumption Large balls generally result What is the effect of ball size in a ball mill? LinkedIn2009年6月1日 Ball size is a critical parameter influencing the performance of a ball mill, particularly for multicompartment ball mills used in cement industry Studies for selection of optimum ball size are reported in the literature (Tarjan, 1981; Duda, 1985) None of these studies is suitable to use in modelling and simulation studiesThe effect of ball size on breakage rate parameter in a pilot

The effect of ball size on breakage rate parameter in a pilot

2009年6月1日 The mill was crashedstopped during various periods Samples were representatively taken from inside the mill in distances of 20–30 cm along the center and edge lengths for selected periods which are 2, 5, 10, 15, 20, 30, 45 and 60 min For modelling of grinding process in pilot scale ball mill, determination of the particle size 2023年10月21日 Barani (2018) studied the effect of ball size distribution on the mill power draw and charge motion regime in a laboratory ball mill using the DEM simulation The drawback of this research is that allFor Peer Review Only ResearchGate2023年5月15日 Ballmills are categorized into four types depending on the motion generated to produce momentum in grinding balls and act upon the material with various milling forces These are planetary, tumbling, vibratory, and attrition mills Cryomilling of starch granules leads to differential effects on molecular size and conformation Ballmilling: A sustainable and green approach for starch

The effects of grinding media shapes on the grinding kinetics

2013年2月1日 The effects of balls and cylinders on the clinker's specific rate of breakage were investigated The results showed that the specific rate of breakage provided by cylinders is higher than that of balls − 200 + 170 mm is an optimum feed size for 20 mm diameter balls and 20 × 20 mm diameter cylindersAt that feed size, the value of Si is 2014年5月1日 The ball size distribution (BSD) in a mill is usually not known, as the measurement of the charge size distribution requires dumping the load and laboriously grading the balls into size classes Fortunately we had one set of data as discussed below The general nonavailability of BSD necessitates the use of ball wear theory to estimate Exploring ball size distribution in coal grinding millsThe effect of ball milling on the crystallinity index of cellulose was also studied by Ahmad and coworkers 26 They treated crystalline cellulose in a planetary ball mill at 600 rpm for 2 hours and studied the differences Ball milling: a green technology for the

Effect of ball size distribution on milling rate ScienceDirect

2009年12月1日 This paper focuses on the determination of the selection function parameters α, a, μ, and Λ together with the exponent factors η and ξ describing the effect of ball size on milling rate for a South African coal A series of batch grinding tests were carried out using three media single sizes, ie 306, 388, and 492 mm Then two ball 2020年5月14日 Effect of Lifter Shapes on the Mill Power in a Ball Mill To cite this article: Zixin Yin et al 2018 IOP Conf Ser: Mater Sci Eng 452 View the article online for updates and enhancements This content was downloaded from IP address 20746135 on 14/05/2020 at 00:52PAPER OPEN ACCESS Effect of Lifter Shapes on the Mill 2013年9月1日 The optimum composition of the makeup ball sizes in ball mills is presented • The effect of various factors was investigated via a grinding circuit simulation • Binary mixtures of two ball sizes always perform better than other mixtures • An equation is proposed for calculating the optimum composition of the makeup ballsOptimum choice of the makeup ball sizes for maximum

Metals Free FullText Effect of Ball Size on the MDPI

2021年10月13日 Commercial powders of pure magnesium were processed by highenergy ball milling The microstructural and morphological evolution of the powders was studied using scanning electron microscopy (SEM), energy dispersive spectrometry (EDX) and Xray diffraction (XRD) From the results obtained, it was determined that the ball size is the 2020年7月2日 In total, 165 scenarios were simulated When the mills charge comprising 60% of small balls and 40% of big balls, mill speed has the greatest influence on power consumption When the mill charge is more homogeneous size, the effect of ball segregation is less and so the power consumption of the mill will be less affectedEffects of Ball Size Distribution and Mill Speed and Their Interactions 2020年11月16日 The raw materials were ground from the big particle size to the smallest possible by using multistep grinding In the laboratory, the common method to be used as the ball mill This work aims to design a simple horizontal ball mill Calcium carbonate material from limestone and eggshells powder was ground using the developed ball millThe design and optimization process of ball mill to reduce

Effect of ball size and powder loading on the milling

2013年12月1日 DOI: 101016/JCERAMINT201304093 Corpus ID: ; Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill @article{Shin2013EffectOB, title={Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill}, author={Hyunho Shin and Sangwook Lee 2013年12月1日 The 50% ball filling of mill container Effect of ball size The effect of ball size on the particle size reduction has been investigated first for varying rotation speed of the container Percent passing and size distributions of the milled Al 2 O 3 powder are shown in Fig 1, Fig 2, respectively, as a function of particle size for varying Effect of ball size and powder loading on the milling 2011年6月10日 The combination of Eqs (2), (8), (9) allows one to describe or predict the effect of ball size on the selection function An example of this is shown in Fig 1The general trend shows that for a given diameter of media, the milling rate increases with particle size, reaches a maximum at the effective particle size x m, and then decreases with an An attainable region analysis of the effect of ball size on

Effect of ball size on steady state of aluminum powder and efficiency

2015年11月1日 Section snippets Powder preparation Aluminum powder of 998% purity (MFCD) was provided by Alfa Aeasar Company Stearic acid (97% purity, Fisher ScientificAC174490010) was used as the process control agent (PCA) and 3 wt% of it was mixed with the aluminum powder prior to millingHigh energy ball milling was done in a 2021年2月19日 The highgrade silica was milled in planetary ball mill and the selected samples were passed through washing, crushing, dehydrating, meshing and drying operations Z, Zhang, Z, Shang, L, Ma, S (2018) Effect of silica sand size and saturation on methane hydrate formation in the presence of SDS Journal of Natural Gas Comparative Study on Improving the Ball Mill Process Please cite this article as: R Panjipour, K Barani, The effect of ball size distribution on power draw, charge motion and breakage mechanism of tumbling ball mill by discrete element method (DEM Examples of movement of the media inside a ball mill

Ball mill characteristics and test conditions Mill Diameter, D

The use of either 254 mm balls or a mixed load of balls with varying sizes results in 31 and 24% decrease in energy requirements, compared to the use of balls with small size (127 mm) View2021年12月1日 The effect of ball size on copper powder particle morphology in drytype milling was studied using a planetary ball mill Spherical copper powders were obtained by ball milling at a high rotation speed and with a ball diameter of 1 mm The experimental results suggest that the particle size and morphology can be controlled by changing the Particle morphology control of metal powder with2022年1月1日 The effects of the balltopowder diameter ratio (BPDR) and the shape of the powder particles on EDEM simulation results and time in the planetary ball mill was investigated BPDR was varied from 1 to 40/3 by changing Effects of balltopowder diameter ratio and powder particle

Effect of ball mill time and wet premilling on the fabrication

2023年8月1日 Sizereduced turning chips (30 g) by cutting process were milled in the planetary ball mill with a ball to powder weight ratio of 3:1 and ethanol (30 mL) using 250 rpm rotation speed Prior to the fabrication of final CpTi metallic powders, a wet milling process was used to obtain more homogeneous initial particle size2021年7月12日 Although there are many parameters that affect the shape and size of the powder, the balltopowder weight ratio (BPR) among them has the most significant effect (Ref 23,24,25) With above analyses, in this study, we firstly propose a method of preparing the gray cast iron powder with graphite structure transplanted from ascast bulkEffect of BalltoPowder Ratio on Morphology, Structure, 2015年1月22日 An investigation was conducted to determine the effect of the ball diameter sizes on milling operation A laboratory size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively Quartz was the material used to perform the experiment and was arranged into 3 monosizes namely 8 mm +56 mm, 4 mm +28 The Effect of Ball Size Diameter on Milling Performance

Exploring the relationship between solventassisted ball

2021年2月1日 However, there has not been an analogous evaluation of ball milling solvent effects for LLZO materials In this work, we investigated the effect of ball milling solvent on Li 64 La 3 Zr 14 Ta 06 O 12 (LLZTO) particle size and composition, and then explored how these resulting particle properties affected sintering behavior and final ionic 2022年3月22日 The effect of ball load composition, by varying the grinding media size distribution (eg alternatively by mixing four groups of 195, 38 mm; 195, 50 mm; 38, 50 mm and 195, 38, 50 mm), on the milling efficiency of a laboratory scale ball mill has been parameters, such as mill speed, charge filling, ball size, and lifter type (Austin et Effect of grinding media on the milling efficiency of a 2014年2月1日 According to the pattern, the residence time thresholds beyond which overfilling a ball mill is likely to occur were defined For a ball mill with an internal diameter smaller than 59 m, the volumebased residence time threshold is set at 2 min; and for a ball mill larger than 59 m in diameter, the threshold is set at 1 min In addition to Effects of slurry filling and mill speed on the net power draw

Experimental investigations and modelling of the ball

2011年9月15日 A laboratory scale planetary ball mill ( Retsch PM400) was equipped with a test rig which enables the observation and recording of the grinding ball motion inside the grinding chamber A high speed camera was fixed on the sun wheel (Fig 1) Lighting is supplied by several LEDs and spotlights, respectively The camera is oriented in a way 2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation It consists of one or more rotating cylinders partially filled with grinding balls (made (PDF) Grinding in Ball Mills: Modeling and Process ControlMotjotji, 2015)The influence of ball size distribution on the grinding effect in a horizontal planetary ball mill was studied by DEM The results showed that the maximum impact energy could be PHYSICOCHEMICAL PROBLEMS OF MINERAL

Dependence of the dissipated energy of particles on the sizes

2021年3月1日 Effect of size and number of particles on dissipated energy The results obtained from the simulation in this work are shown below Fig 2 illustrates snapshots of the states of the particles and balls in the mill pot at different values of D p and BPR Large and small D p mimic the early and final stages of particle breakage, respectivelyThe effect of ball load composition, by varying the grinding media size distribution (eg alternatively by mixing four groups of 195, 38 mm; 195, 50 mm; 38, 50 mm and 195, 38, 50 mm), on the milling efficiency of a laboratory scale ball mill has been parameters, such as mill speed, charge filling, ball size, and lifter type (Austin et Effect of grinding media on the milling efficiency of a 2022年6月5日 balls reduced the number of particles coarser than 1 mm by about 5% In case the feed to ball mill was equal to 1200 Mg/h, it resulted in a reduction of 60 Mg/h of the weight of coarse particles in circulation It also enabled the processing of a larger feed size without the risk of balls being thrown from the millAnaliza efektywności mielenia w młynach kulowym i

Predicting the effect of operating and design variables on

2013年4月1日 The predicted influence of particle and ball size, mill filling, speed and frequency was in general qualitative agreement with evidence from the literature, as well from predictions using the traditional scaleup methods of Herbst and Fuerstenau (1980) and Austin et al (1984) The effect of ball size on the breakage parameter in a pilot 2019年5月16日 The results of particle size analyzer are shown in table 1 It can be seen that the increase in diameter of the steel ball does not have any certain correlation to the decrease of the particle size The smallest particle having average size of 2738 nm is produced by the ¼ inch ball diameter The sizes of 4901PAPER OPEN ACCESS 7KHHIIHFWRIWKHEDOOVL 2020年1月29日 An investigation was conducted to determine the effect of the ball diameter sizes on milling operation A laboratory size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively Quartz was the material used to perform the experiment and was arranged into 3 monosizes namely 8 mm +56 mm, 4 mm +28 The Effect of Ball Size Diameter on Milling Performance

Ball size distribution for the maximum production of a

2015年11月1日 Abstract Ball size distribution is commonly used to optimise and control the quality of the mill product A simulation model combining milling circuit and ball size distribution was used to determine the best makeup ball charge The objective function was to find the ball mix that guarantees maximum production of the floatable size range (ie 2023年3月22日 The size of the ball in a ball mill has a significant effect on the mill’s performance, including the production rate, material grindability, and power consumption Large balls generally result What is the effect of ball size in a ball mill? LinkedIn2009年6月1日 Section snippets Experimental studies Comparative tests were conducted using the different preassembled ball charges given in Fig 1 in a pilot scale ball mill having 12 m inside diameter and 06 m length These six different ball media grading used during the tests runs was identical to industrial standard ball mill media proposed by Bond with The effect of ball size on breakage rate parameter in a pilot

The effect of ball size on breakage rate parameter in a pilot

2009年6月1日 The mill was crashedstopped during various periods Samples were representatively taken from inside the mill in distances of 20–30 cm along the center and edge lengths for selected periods which are 2, 5, 10, 15, 20, 30, 45 and 60 min For modelling of grinding process in pilot scale ball mill, determination of the particle size 2023年10月21日 Barani (2018) studied the effect of ball size distribution on the mill power draw and charge motion regime in a laboratory ball mill using the DEM simulation The drawback of this research is that allFor Peer Review Only ResearchGate2023年5月15日 Ballmills are categorized into four types depending on the motion generated to produce momentum in grinding balls and act upon the material with various milling forces These are planetary, tumbling, vibratory, and attrition mills Cryomilling of starch granules leads to differential effects on molecular size and conformation Ballmilling: A sustainable and green approach for starch

The effects of grinding media shapes on the grinding kinetics

2013年2月1日 The effects of balls and cylinders on the clinker's specific rate of breakage were investigated The results showed that the specific rate of breakage provided by cylinders is higher than that of balls − 200 + 170 mm is an optimum feed size for 20 mm diameter balls and 20 × 20 mm diameter cylindersAt that feed size, the value of Si is

effect of ball size in ball mill

Effect of ball size and powder loading on the milling efficiency 2013年12月1日 Here we report that there exists an optimal ball size for efficient milling at a