-

صفحة رئيسية > المنتجات >

silican ball mill balls

2021-05-11T16:05:09+00:00

Original Article refinement of SiC particles by a novel

2020年7月1日 The diameters of the milling balls are, 15, 125, 10, 8, and 5 mm mixed with a ratio of 3: 5: 25: 45: 212 which are named as #1 through #5, respectively The Abstract Luminescent silicon nanocrystals (SiNCs) have attracted scientific interest for their potential use in LEDs, displays, lasers, photovoltaic Photophysical properties of ball milled silicon In order to explore the impact of different ball milling technical parameters on the grain size of nano silicon powder, this paper adopted the orthogonal experimental design in The Impact of Ball Milling Process Parameters on the Preparation

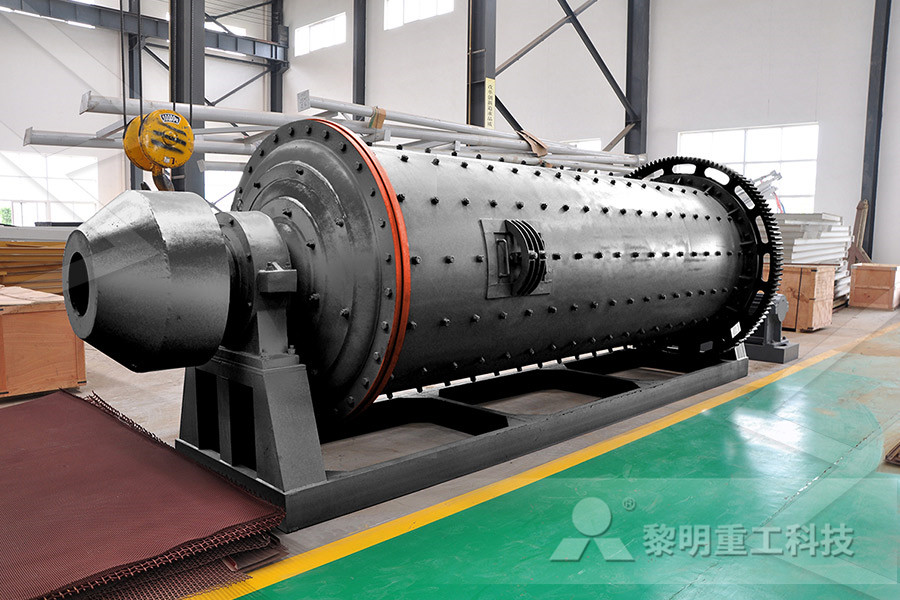

Ball Mill an overview ScienceDirect Topics

Ball mills are commonly used for crushing and grinding the materials into an extremely fine form The ball mill contains a hollow cylindrical shell that rotates about its axis This 2020年1月15日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, Silicon Powder Properties Produced in a Planetary Ball Mill 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role A Review of the Grinding Media in Ball Mills for Mineral

Ballmilling: A sustainable and green approach for starch

2023年5月15日 Ballmilling is a lowcost and green technology that offers mechanical actions (shear, friction, collision, and impact) to modify and reduce starch to nanoscale 2020年10月1日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, Silicon Powder Properties Produced in a Planetary Ball Mill Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the Ball milling: a green technology for the preparation and

Surface modification of silica powder by mild ball milling

2022年11月5日 Dry method Silane coupling agent Modification Silica Ball mill 1 Introduction Silane coupling agents have been commonly utilized for improving the 2021年11月17日 Commercial Nb powder of particle sizes of − 44 µm was employed by using the planetary ball mill equipped with stainless still vials with still balls in ethanol A balltopowder mass ratio of Wet ball milling of niobium by using ethanol, determination 2020年10月1日 Fig 1 a shows the oscillatory ball mill (Retsch® MM400) used in this study and a scheme (Fig 1 b) representing one of its two 50 mL milling jars Each jar is initially filled with a mass M of raw material and a single 25 mmdiameter steel ball The jars vibrate horizontally at a frequency chosen between 3 and 30 Hz The motion of the jar follows a Evolution of grinding energy and particle size during dry ball

Materials Free FullText Effect of Ball Milling Time on the

2023年8月23日 The grinding process employed zirconia balls as the grinding medium, while the grinding tank was constructed using polytetrafluoroethylene and had a capacity of 1L The ball mill used was a XQXM2 planetary ball mill A consistent ratio of 10:1 for the ball material was upheld during the ball milling process, and a grinding speed of 200 r 2013年12月1日 It was found that the ball mill consumed 5467 kWh/t energy to reduce the F 80 feed size of 7222 µm to P 80 product size of 2754 µm while stirred mill consumed 3245 kWh/t of energy to produce the product size of 2356 µm It also showed that stirred mill produced finer product than the ball mill at around 40% lesser consumption of energyEffect of ball size and powder loading on the milling 2022年11月5日 In this study, a catalyst and solventfree ball mill treatment was conducted to modify the silica powders by the mild ball milling process as the simple and the low manufacturing cost method The effects of the amount of the modifier, ball milling time, and washing process were examined 2 ExperimentalSurface modification of silica powder by mild ball milling

Ball milling as a synthesis method Aalto

2022年4月4日 Selection of ball mills is discussed in Highenergy and lowenergy ball millschapter [1, p48–49] Figure 2 Main factors that affect the endproduct and its properties during ball milling [1, p48–49] (Figure: Aki Saarnio) Shape of the milling vial Internal shape of the ball mill can be flatended or concaveended (roundended)Shop MSE Supplies for a wide range of grinding media and grinding balls Call Us: +1 (520)7896673 Home; Products Arc Melters and Quenchers; Ball Mills, Milling Jars, Milling Media; Battery Testing Systems; Ceramic Beads Balls Fine Grinding Media Milling Media Set for 500 ml 304SS Roller Mill Jar; Planetary Mill Jar Media Sets;Milling Balls Grinding Media Grinding Balls MSE Supplies8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topics

/ tulane university ball mill siliconmd at main

Contribute to chengxinjia/ development by creating an account on GitHubThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batch The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short Planetary Ball Mill PM 100 RETSCH highest fineness2023年11月6日 Retsch High Energy Ball Mill Emax, 200–240 V, 50/60 Hz, High Energy Ball Mill with 2 Grinding Stations £2507000 Add to cart Only 0 Available Subject to Stock Unsold Usually Shipped in 46 Weeks Add Largest Selection Of Laboratory Ball Mills Only

Silicon Carbide Grinding Media Grinding Balls

2023年6月7日 Silicon Carbide Balls are very highcost grinding media that are used for milling the same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination SAM's silicon carbide grinding 2023年3月9日 A ball mill is an efficient tool for grinding silica sand because it can grind the material to a very fine and uniform particle size The ball mill uses a rotating drum filled with steel balls or Why is a ball mill used for grinding silica sand? LinkedIn2022年4月4日 Selection of ball mills is discussed in Highenergy and lowenergy ball millschapter [1, p48–49] Figure 2 Main factors that affect the endproduct and its properties during ball milling [1, p48–49] (Figure: Aki Saarnio) Shape of the milling vial Internal shape of the ball mill can be flatended or concaveended (roundended)Ball milling as a synthesis method Aalto University Wiki

Ball Mill Balls Manufacturing Of High Quality Ball Mill Ball

Product Description Ball mill balls are a type of ball used in ball mills, usually made of highhardness materials such as steel, ceramics, hard alloys, etc Ball mill steel balls is an important part of the ball mill, its main function is to carry out the grinding operation in the ball mill, and the material is crushed into the required size2021年5月23日 Ball Milling A ball mill is a type of mill used to grind and mix materials to be used in processes for mixing minerals, paints, pyrotechnics, ceramics, and selective laser sintering It works by the principle of impact and friction: the size reduction is achieved when the grinding media characteristic of this equipment (balls or spheres Ball Milling CarboSystem2016年4月22日 Mechanochemistry using ball mills is a promising technique with applications in organic and inorganic chemistry as well as material sciences [1–4]During ball milling, up to 80 % of the energy that is generated in the mill is dissipated as heat []This is why measurement and control of the temperature in the ball mills is important, for Temperature progression in a mixer ball mill Springer

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a (4%) by ball milling with zirconium balls at 2400 rpm at room temperature for different grinding times ranging from 15 to 5 minutes The resulting nanofibrils had a width of 2–18 nm, as shown by TEM and AFM Interestingly, in contrast with other described processes, in this case, ball milling did not 2016年10月20日 Grinding Balls Steel balls ranging from ¾ to 5 in in diameter are used Rods range from 1½ to 4 in in diameter and should be 3 to 4 in shorter than the inside mill length Tube mills are usually fed balls smaller than 2 in, whereas 4 or 5in balls are more commonly used for ballmill grindingGrinding Balls Rods 911 MetallurgistZys Precision Ceramic Balls G3 G5 G10 G25 G40 Silicon Nitride Si3n4 Zirconia Zro2 Ceramic Bearing Ball 7938mm for Full Ceramic Ball Bearing US$ 011 / Piece 1 Piece (MOQ)China Zirconia Balls, Zirconia Balls Manufacturers, Suppliers,

10 Best Silicone Balls Their Reviews [Updated 2021]

2023年11月1日 For the gym junkies, it’s important to consult your physician first before using this gym buddy A ball with a lot of purposes – can be a toy, distraction tool, or a gyming tool 4 Ferswe Massage Lacrosse Ball Ferswe Massage Lacrosse Ball,100% Silicone Ball for Myofascial Release, Trigger Point Therapy,The ball mill Ball milling is a (4%) by ball milling with zirconium balls at 2400 rpm at room temperature for different grinding times ranging from 15 to 5 minutes The resulting nanofibrils had a width of 2–18 nm, as shown by TEM and AFM Interestingly, in contrast with other described processes, in this case, ball milling did not Ball milling: a green technology for the preparation and 2023年11月1日 Uses: Alumina Oxide ceramic balls may be used at temperatures up to 3180 ºF Ceramic balls are extremely hard, resistant to abrasion, and immune to all furnace atmospheres Applications where alumina oxide balls are used include chemical pumps, downhole pumps, valves, bearings, gages, flowmeters, etcCeramic Balls SKF

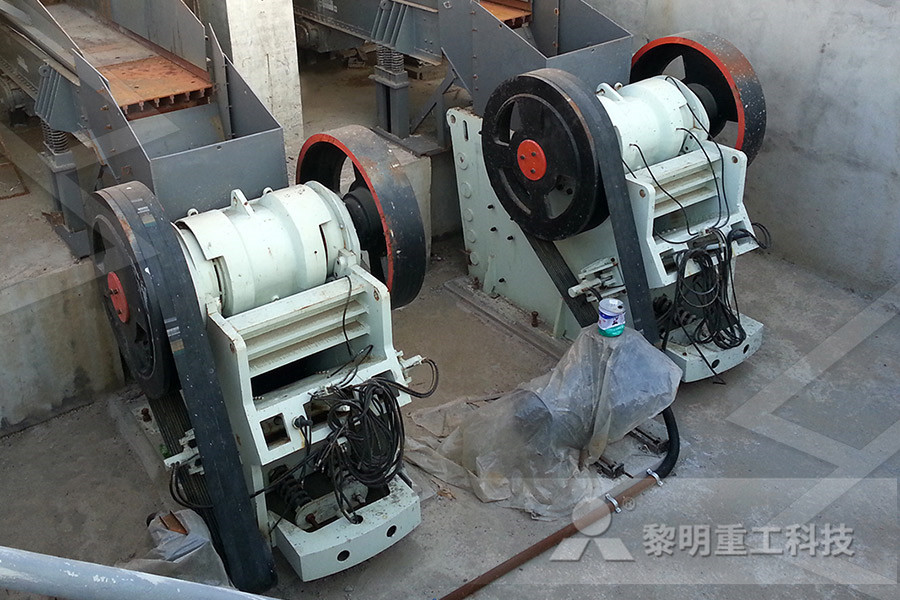

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation It consists of one or more rotating cylinders partially filled with grinding balls (made 2012年8月28日 Abstract and Figures Silica nanoparticles were synthesized from rice husk ash at room temperature by using a high energy planetary ball mill The milling time and mill rotational speed were Ball Milling Synthesis of Silica Nanoparticle from Rice Husk The grinding jars are arranged eccentrically on the sun wheel of the planetary ball mill The direction of movement of the sun wheel is opposite to that of the grinding jars in the ratio 1:2 (or 1:25 or 1:3) The grinding balls in the grinding jars are subjected to superimposed rotational movements, the socalled Coriolis forcesPlanetary Ball Mill PM 400 RETSCH powerful and quick

Minerals Free FullText Effects of Ball Size on the Grinding

2019年10月31日 As the ball size increases, greater size reduction of the talc particle and loss of crystallinity occur during grinding This is due to the reduced kinetic energy of collision between rotating balls in the mill with 01 mm balls when compared with 2 mm and 1 mm balls [31,32]Contribute to changjiangsx/ development by creating an account on GitHub/ ball mtw grinding mill supplier mexico porous Silicon nitride balls have the characteristics of low density, high hardness, low friction coefficient, wear resistance, selflubrication and good rigidity Thus the Si3N4 balls are especially suitable for rolling elements of highspeed, highprecision and longlife hybrid ceramic ball bearings ZYS Si3N4 ceramic ball adopts spray drying granulating, cold How are Si3N4 ceramic balls produced? zysbearing

Sic Balls CS Ceramic

Balls are made of ceramic SiC with high hardness, selflubricating properties, low thermal expansion coefficient and extreme corrosion resistance Sic Balls are mainly used in metallurgy,chemical industry,nonferrous metal smelting,especially in liquid aluminum,liquid copper and other industries,with long service lifeFracture and Thermally ShockResistant SiliconNitride Ceramic Balls Color: Black Max Temperature: 1470° F Porosity: 13% Compressive Strength: 550, 000 psi Often used to create bearings, siliconnitride ceramic is harder than many types of bearing steel but is lightweight and can be easily polishedSilicon Nitride McMasterCarrBall mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications Cooling, heating cryogenic grindingBall Mill RETSCH powerful grinding and homogenization

Wet Dry Silica Sand Ball Mill for Silica Sand Grinding

Silica sand ball mill is a professional ball mill equipment for grinding silica sand In some areas, it is also called silica sand grinding mill or silica sand grinding machineSilica sand is a chemically stable silicate mineral with particle size between 002 and 335mmBoth silica sand and quartz sand are mainly composed of SiO 2, but their hardness and shape are Si@SiOx/grapheme nanosheet (Si@SiOx/GNS) nanocomposites as highperformance anode materials for lithiumion batteries are prepared by mechanically blending the mixture of expanded graphite (EG) with Si nanoparticles, and characterized by Raman spectrum, Xray diffraction (XRD), field emission scanning electron microscopy, and transmission Frontiers Si@SiOx/Graphene Nanosheets Composite: Ball Milling In order to explore the impact of different ball milling technical parameters on the grain size of nano silicon powder, this paper adopted the orthogonal experimental design in combination with fitting analysis, and set the agitator shaft speed of the ball mill and the milling time as the influence factors Then this paper studied the impact of The Impact of Ball Milling Process Parameters on the Preparation

Ball Milling method for synthesis of nanomaterials

2023年9月4日 1 As the name suggests, the ball milling method consists of balls and a mill chamber Therefore over all a ball mill contains a stainless steel container and many small iron, hardened steel, silicon carbide, or tungsten carbide balls are made to rotate inside a mill (drum) 2 The powder of a material is taken inside the steel container2023年8月15日 球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿以及玻璃陶瓷等生产行业,对各种矿石和其它可磨性物料进行干式或湿式粉磨。球磨机适用于粉 球磨机百度百科2020年5月25日 Vibratory Ball Mill Applications: It is widely used in the fields of electronics, ceramics, chemicals, powder metal, tungsten, Calcium carbide, rubber compounds, magnetic materials and highfrequency porcelain material and pharmaceutical of radio industries Vibration ball mill is a new model of powder equipment with high efficiency, Vibratory Ball Mill labmills

Wet ball milling of niobium by using ethanol, determination

2021年11月17日 Commercial Nb powder of particle sizes of − 44 µm was employed by using the planetary ball mill equipped with stainless still vials with still balls in ethanol A balltopowder mass ratio of 2020年10月1日 Fig 1 a shows the oscillatory ball mill (Retsch® MM400) used in this study and a scheme (Fig 1 b) representing one of its two 50 mL milling jars Each jar is initially filled with a mass M of raw material and a single 25 mmdiameter steel ball The jars vibrate horizontally at a frequency chosen between 3 and 30 Hz The motion of the jar follows a Evolution of grinding energy and particle size during dry ball 2023年8月23日 The grinding process employed zirconia balls as the grinding medium, while the grinding tank was constructed using polytetrafluoroethylene and had a capacity of 1L The ball mill used was a XQXM2 planetary ball mill A consistent ratio of 10:1 for the ball material was upheld during the ball milling process, and a grinding speed of 200 r Materials Free FullText Effect of Ball Milling Time on the

Effect of ball size and powder loading on the milling

2013年12月1日 It was found that the ball mill consumed 5467 kWh/t energy to reduce the F 80 feed size of 7222 µm to P 80 product size of 2754 µm while stirred mill consumed 3245 kWh/t of energy to produce the product size of 2356 µm It also showed that stirred mill produced finer product than the ball mill at around 40% lesser consumption of energy2022年11月5日 Fig 3 shows a typical TGDTA curve of the silica powder modified by 05 ml of HTMS after ball milling for 24 h The DTA curve showed two peaks at approximately 130 and 300 °C The first endothermic peak corresponds to the loss of physically adsorbed and/or hydrogenbonded water from the silica powder [22]The second exothermic peak Surface modification of silica powder by mild ball milling2022年4月4日 Selection of ball mills is discussed in Highenergy and lowenergy ball millschapter [1, p48–49] Figure 2 Main factors that affect the endproduct and its properties during ball milling [1, p48–49] (Figure: Aki Saarnio) Shape of the milling vial Internal shape of the ball mill can be flatended or concaveended (roundended)Ball milling as a synthesis method Aalto

Milling Balls Grinding Media Grinding Balls MSE Supplies

Shop MSE Supplies for a wide range of grinding media and grinding balls Call Us: +1 (520)7896673 Home; Products Arc Melters and Quenchers; Ball Mills, Milling Jars, Milling Media; Battery Testing Systems; Ceramic Beads Balls Fine Grinding Media Milling Media Set for 500 ml 304SS Roller Mill Jar; Planetary Mill Jar Media Sets;8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect TopicsContribute to chengxinjia/ development by creating an account on GitHub/ tulane university ball mill siliconmd at main

Planetary Ball Mill PM 100 RETSCH highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batch The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short

silican ball mill balls

Original Article refinement of SiC particles by a novel 2020年7月1日 The diameters of the milling balls are, 15, 125, 10, 8, and 5 mm mixed with a ratio of