-

صفحة رئيسية > المنتجات >

manufacturing sand and aggregates for concrete in india

2020-02-26T05:02:11+00:00

Overview of Indian aggregate industry Indian Cement Review

2021年7月1日 Manufactured sand is one subset of aggregates Cement is used as a binder with aggregates The aggregate industry in India is an unorganised sector and undergoing a lot of changes, which were long pending, writes Sanjay Nikam, a founding 2014年5月1日 PDF The reduced availability of natural sands, particularly along the east coast of India, and the need to better utilise sandsize (PDF) A REVIEW ON NEED OF MANUFACTURED 2015年1月1日 In this study an attempt is made to use steel slag, a byproduct from steel industry as replacement for coarse aggregate in (PDF) Study on replacement of coarse aggregate

Construction Aggregates Manufacturers Suppliers in India

Find here Construction Aggregates, Fine Aggregate manufacturers OEM manufacturers in India Get Contact details address of companies manufacturing and supplying 2020年7月29日 Using MSand in concrete is most economical also This paper presents use of MSand in concrete manufacturing, Mix design and quality expectations from the Use of MSand in Concrete Manufacturing, Mix Design 2023年10月23日 some of the study’s findings from Dr CS Viswanatha, Chief Executive, Torsteel Research foundation in India has concluded that compared to concrete made MANUFACTURED SAND, A SOLUTION AND AN

Manufactured sand – a solution to the global sand shortage?

2020年11月30日 In India, the possibility of replacing some of the sand in the concrete mix with waste plastic is being investigated Alternative ideas for “green concrete” have also 2022年1月1日 Hence, alternatively manufactured sand is used in place of fine aggregate in the concrete Due to rapid urbanization in India more public construction activities were in Assessment of usage of manufactured sand and recycled aggregate 2023年11月2日 Construction aggregate, or simply aggregate, is a broad category of coarse to mediumgrained particulate material used in construction, including sand, Aggregates India Manufacturers and Suppliers

Aggregates for Concrete

2017年8月5日 62—Definition of lightweightaggregate concrete 63—Lowdensity concretes and associated aggregates 631—Structural lightweight concrete and associated aggregates 632—Moderatestrength lightweight concrete and associated aggregates 633—Properties Chapter 7—Recycled aggregates, p E123 71—Introduction to 2023年2月7日 sand is manufactured sand (M sand), which is better in terms of quality and fulfils the requirements of suitable material for use in concrete M sand is manufactured by any of the methodsby crushing of coarse aggregates (20mm 10mm) in separate sand plants or using 3 stage VSI crushers Then this material is further processed eitherIndex Terms IJSER2021年1月24日 Natural resources are being continuously extracted for the production of concrete which leads to degradation of the ecosystem This is also a challenge for sustainability to save Nature This study seeks to Sustainable Alternate Materials for Concrete

Sustainable use of mine waste and tailings with suitable

2018年6月26日 Utilization of mine waste rocks and tailings in concrete as aggregates will help in sustainable and greener development The literature shows the potential use of iron ore tailings as a replacement of natural fine aggregates As natural sand reserves are d epleting day by day, there is a need for substitution for sand in concrete2023年3月2日 Thus, there is a need for river sand and aggregates alternatives in concrete, namely manufactured sand (msand) from primary solid rock materials and secondary waste materials Ong, DE; Doh, JH A sustainable solution to excessive river sand mining by utilizing byproducts in concrete manufacturing: A stateoftheart review Clean Life Cycle Assessment of River Sand and Aggregates Alternatives in ConcreteManufacturing sand (m sand) is a way to preserve natural riverbanks and shorelines where sand would otherwise be extracted, reduce energy consumption, and utilize aggregate waste as a raw material for sellable product Sand is a key ingredient in concrete, cement and asphalt As the cities around the world continue to grow, the demand for Manufacturing sand

Manufactured Sand Process, Advantages and Types

2021年11月3日 Manufacturing sand is a way to preserve natural riverbanks and shorelines where sand would otherwise be extracted, reduce energy consumption, and utilize aggregate waste However, sand scarcity is a problem affecting many countries, including India With natural sand, which is found in riverbeds and coastal regions, becoming Owing to our years of experience in this field, we are reckoned in manufacturing and supplying with a broad array of Crush Sand And Aggregates for our important clients in Pune, Maharashtra, India A good quality concrete product is a result of using latest manufacturing technology, strict quality control procedures and superior quality raw Crush Sand And Aggregates at Best Price in Pune TradeIndia2021年1月1日 Sea sand overcomes the upcoming demand in the requirement of the river sand and Msand as fine aggregate in construction industry [3], [4]Sea sand samples as fine aggregate are collected from the coast of Arabian Sea of India near to the place Snehatheeram beach located in Kerala [6] is the floor of sea shore Sea sand contains Investigation on behaviour of Msand and sea sand based concrete

Usage potential and benefits of processed coconut shells in concrete

2023年4月1日 Concrete is a heterogeneous material that is made by mixing cement, sand, coarse aggregates (CA), and water [1] Manufacturing sand (M−sand) was used as FA and sieve analysis was carried out in accordance with IS 383 Specification for Coarse and Fine Aggregates From Natural Sources for Concrete, Indian Stand (1970) 1–24 Google 2022年4月7日 Geopolymer concrete (GPC) is a new material in the construction industry, with different chemical compositions and reactions involved in a binding material The pozzolanic materials (industrial waste Geopolymer Concrete: A Material for Sustainable 2020年12月30日 The compression and split tensile behavior of sea shell aggregate mixed concrete comparatively with plain sand concrete was studied under different curing periods such as 7 days, 14 days and 28 days(PDF) Natural aggregates used for Light weight

Experimental Studies on Concrete Using the Partial

2020年11月24日 This study is about the usage of finely grounded glass waste in concrete as replacement material to cement in of 5, 10, 15 and 20%, and manufactured sand had been used as fine aggregate fully Compressive and Split Tensile strength tests for the hardbitten concrete were done at the time period intervals of (7–14–28) days2023年3月15日 Ordinary Portland Cement of grade 53, which complies with Indian Standard IS:12269–2013, is used as a binding material in cement mortar manufacturing [29] Tables 1 list the physical and chemical characteristics of cement and Table 2 represents the chemical properties of cement and slag sand The authors employed the EDS test to Effect of slag sand as river sand and its influence on 2017年12月15日 Majority of waste foundry sands are categorized as nonhazardous waste (that is noncorrosive, ignitable, reactive or toxic) and have shown good durability 3 In general, increase in substitution leads to decrease in workability of concrete attributed to presence of finer particles of sand and additivesWaste foundry sand in concrete: A review ScienceDirect

Manufactured sand – a solution to the global sand shortage?

2020年11月30日 First, manufactured sand is more uniform in structure compared with natural sand It also has an advantage when it comes to concrete production, because manufactured sand is less needed in the concrete mix by a margin of 5 to 20% compared with natural sand to fill the voids volume between the particles Even though the 2022年3月24日 About 65 to 80% of the concrete mix is composed of sand and aggregates In the UK alone, it requires 200 million tonnes of aggregates every year for their construction purposes This demand for sand in the State of India stood for 24 million tonnes a year, against the supply of 14 million tonnes (Nagesh Prabhu 2015) The location of licensed The way forward to sustain environmental quality through2022年4月9日 About 7% of the world’s energy is used to extract, handle and process raw resources (Beccali et al 2010)The construction industry uses 40% of the natural resources extracted from the earth’s crust and generates 35% of the solid waste globally (Rosado et al 2017)Haphazard mining of the river sand and other natural aggregates poses a danger Comparative Environmental Impacts of Recycled Concrete Aggregate

Sustainability assessment of recycled aggregate concrete

2023年3月14日 Due to the quantity of cement paste of RCA, the amount of CO 2 captured is much more significant for sand (31–39 kgCO 2 /t for 0–4 mm) than for gravel (16 kgCO 2 /t for 4–16 mm) 61 The impact of accelerated carbonation on the environmental assessment of RAC was carried out by comparing the environmental impacts of concretes formulated 2022年1月1日 The workability of fresh concrete was tested using a slump, compaction factor, flow, and vee bee tests with 20% of pozzolanic material for cement and by increasing the percentage of manufactured sand it seems to decrease in workability on concrete [14] and pumpable concrete which Bacillus subtilis bacteria added and manufactured sand Assessment of usage of manufactured sand and recycled aggregate 2020年1月1日 Also, Needhidasan and Sai [57] used ePrinted Circuits Boards (PCB) (20 mm size) of as the partial replacement of aggregate up to 125% along with manufacturing sand for M20 grade concrete The Experimental study on use of Ewaste plastics as coarse aggregate

INDIAN STANDARDS FOR

2021年9月13日 INDIAN STANDARDS FOR Public Works Departments, Development Authorities, Municipal Corporations, Housing Boards/Corporations, etc CEMENT IS No Title IS 269:2015 Ordinary Portland cement IS 455:2015 Portland slag cement • IS 383:2016 Coarse and fine aggregates for concrete2013年1月1日 Msand is made from crushed and granulated mining waste rock It has a more consistent size distribution than river sand due to a controlled manufacturing process and a Buildings 2023, 13, 1463 3 (PDF) Manufactured sand, a solution and an 2016年8月31日 Steel slag offers the maxi mum strength and is mos tly suited for areas that are not exposed to marine conditions Increase in strength initially is attrib uted to shape effect and decrease in (PDF) Steel Slag Utilization — Overview in Indian Perspective

Properties and microstructure of concrete using pozzolanic

2019年8月13日 The overuse level of cement and natural sand for civil industry has several undesirable social and ecological consequences As an answer for this, industrial wastes called as byproducts (pozzolanic materials) such as fly ash, GGBFS, silica fume and metakaolin can be used to interchange partially cement and natural sand by 2023年10月12日 On the other hand, M sand is utilised for concrete or mortar mix The size of M sand ranges from 0 to 475 mm while the size of P sand ranges from 0 to 236 mm Revolutionizing construction: M sand solutions Global aggregates demand is estimated to rise to 60 billion tonnes per annum by 2030 due to rising population and urbanizationM Sand: Price, types and advantages for sustainable 2022年8月1日 In terms of concrete manufacturing, India is now ranked second worldwide Aggregates include things like sand, gravel, and crushed stone As it dries, the cement acts as a binder, setting and hardening Once co2 in the air reacts with the cement, it bonds the particles together and creates a mass that resembles rock Q What distinguishes List of Top Concrete Manufacturing Companies in India

Chapter 8 Pavement materials: Aggregates IIT Bombay

2012年12月23日 A maximum value of 40 percent is allowed for WBM base course in Indian conditions For bituminous concrete, a maximum value of 35 is specified 833 Impact test The aggregate impact test is carried out to evaluate the resistance to impact of aggregates Aggregates passing 125 mm sieve and retained on 10 mm sieve is filled in a cylindrical 2021年1月8日 Concrete is a mix of several different materials: water, fine aggregates (or sand), coarse aggregates (or gravel), chemical additives, and, most importantly, cement Cement is what binds all of these ingredients together to give concrete its durability and distinctive, grey appearance Cement production, however, also generates most of Concrete MIT Climate PortalJuly 1, 2021 By admin In spite of challenges, the aggregate industry looks attractive As captured earlier in the reports, we estimate the growth of aggregates industry in double digits Non availability of high quality fine aggregates and restriction on natural sand dredging will open an opportunity for manufactured concrete/plaster sandFuture evolution drivers of aggregate industry Indian Cement

Cradletogate environmental impacts of the

It is estimated that 30% of aggregate and sand produced in SA (an average of 321 Mt for 2005 2008, based on ASPASA production figures) is used for concrete production, which includes onsite production of concrete and 2020年3月22日 Global production of aggregates was 21 B tonnes in 2007 and 40 B tonnes in 2014 [1,2]The most recent data presents value of 50 B tonnes of sand and gravel yearly consumption []According to Big Market Research (BMR), Aggregates Market Development by 2026 report [] and Grand View Research (GVR), Aggregates Market Size, Share and Properties of Concrete with Recycled Concrete Aggregate 2021年1月1日 The fineness modulus of foundry sand ranges from 09 to 16 compared to the sand used as a fine aggregate of concrete which has value ranges from 23 to 31 Therefore, it is necessary to blend foundry sand with coarser sands to meet the requirements of the specifications [57] Feasibility of sustainable construction materials for concrete paving

(PDF) Experimental Study on the Use of Basalt Aggregate in Concrete Mixes

2015年5月4日 Kishore et al [61] tested the basalt replacement of coarse aggregate at a rate of 0% to 100% by steps of 25% increments and found that the utilization of basalt increased the compressive strength 2020年8月27日 As a binding medium, concrete is one of the most popular and widely used civil engineering materials for sustaining the fastgrowing global population and for rapid urban development, especially in developing countries []The emergence of concrete mixed with cement, aggregates, water, and reinforced steel bars also has uses in the areas of The Utilization of Agricultural Waste as AgroCement in Concrete2021年3月1日 The results show that compared with manufactured sand (MS) concrete, the working performance of concrete with DMS is increased by 1619% on average, and the strength is increased by 71% on Cleaner Production of Concrete by Using Industrial By

Studies on use of Copper Slag as Replacement Material for River Sand

2014年8月20日 This work focuses on the use of copper slag, as a partial replacement of sand for use in cement concrete and building construction Cement mortar mixtures prepared with fine aggregate made up of different proportions of copper slag and sand were tested for use as masonry mortars and plastering Three masonry wall panels of 2021年10月16日 This paper summarizes the developments with regard to the use of plastic waste as a constituent of construction material Inclusion of plastic waste as a binder, aggregate, fine aggregate, modifier or substitute of cement and sand in the manufacturing of bricks, tiles, concrete and roads has been comprehensively reviewedRecycling/reuse of plastic waste as construction material for 2022年8月26日 Ambuja Cements Ltd, HO POABS GROUP, Thriveni Sand (Thriveni Earthmovers Private Limited), Robo Silicon Private Limited, and Tavara Mines Minerals, among others, are significant players in the India sand market The India sand market is expected to grow at a CAGR of about 67% annually in the forecast period of 20222027 Top Sand Companies, Suppliers in India Expert Market

Evaluation of Durability Parameters of Concrete with Manufacture Sand

2017年6月28日 Manufacturing of Msand involves three stages, Coarse and Fine Aggregate for Concrete Specification, (Bureau of Indian Standards (BIS), New Delhi, 2016) strength and durability studies of concrete made with recycled concrete aggregate, Msand and different mineral admixtures Indian J GeoMar Sci 45(4), 556–565 (2016)2017年8月5日 62—Definition of lightweightaggregate concrete 63—Lowdensity concretes and associated aggregates 631—Structural lightweight concrete and associated aggregates 632—Moderatestrength lightweight concrete and associated aggregates 633—Properties Chapter 7—Recycled aggregates, p E123 71—Introduction to Aggregates for Concrete2023年2月7日 sand is manufactured sand (M sand), which is better in terms of quality and fulfils the requirements of suitable material for use in concrete M sand is manufactured by any of the methodsby crushing of coarse aggregates (20mm 10mm) in separate sand plants or using 3 stage VSI crushers Then this material is further processed eitherIndex Terms IJSER

Sustainable Alternate Materials for Concrete

2021年1月24日 Natural resources are being continuously extracted for the production of concrete which leads to degradation of the ecosystem This is also a challenge for sustainability to save Nature This study seeks to 2018年6月26日 Utilization of mine waste rocks and tailings in concrete as aggregates will help in sustainable and greener development The literature shows the potential use of iron ore tailings as a replacement of natural fine aggregates As natural sand reserves are d epleting day by day, there is a need for substitution for sand in concreteSustainable use of mine waste and tailings with suitable 2023年3月2日 Thus, there is a need for river sand and aggregates alternatives in concrete, namely manufactured sand (msand) from primary solid rock materials and secondary waste materials Ong, DE; Doh, JH A sustainable solution to excessive river sand mining by utilizing byproducts in concrete manufacturing: A stateoftheart review Clean Life Cycle Assessment of River Sand and Aggregates Alternatives in Concrete

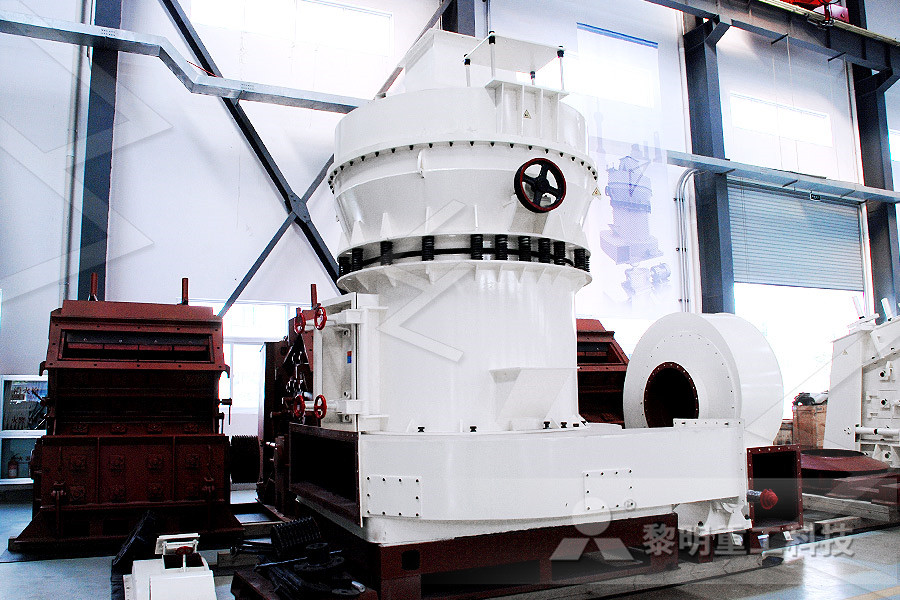

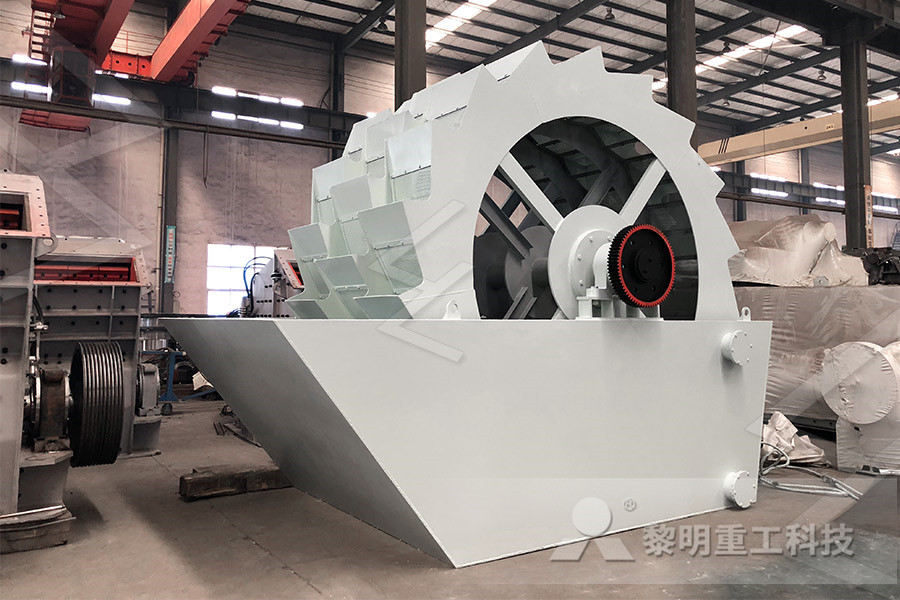

Manufacturing sand

Manufacturing sand (m sand) is a way to preserve natural riverbanks and shorelines where sand would otherwise be extracted, reduce energy consumption, and utilize aggregate waste as a raw material for sellable product Sand is a key ingredient in concrete, cement and asphalt As the cities around the world continue to grow, the demand for 2021年11月3日 Manufacturing sand is a way to preserve natural riverbanks and shorelines where sand would otherwise be extracted, reduce energy consumption, and utilize aggregate waste However, sand scarcity is a problem affecting many countries, including India With natural sand, which is found in riverbeds and coastal regions, becoming Manufactured Sand Process, Advantages and TypesOwing to our years of experience in this field, we are reckoned in manufacturing and supplying with a broad array of Crush Sand And Aggregates for our important clients in Pune, Maharashtra, India A good quality concrete product is a result of using latest manufacturing technology, strict quality control procedures and superior quality raw Crush Sand And Aggregates at Best Price in Pune TradeIndia

Investigation on behaviour of Msand and sea sand based concrete

2021年1月1日 Sea sand overcomes the upcoming demand in the requirement of the river sand and Msand as fine aggregate in construction industry [3], [4]Sea sand samples as fine aggregate are collected from the coast of Arabian Sea of India near to the place Snehatheeram beach located in Kerala [6] is the floor of sea shore Sea sand contains 2023年4月1日 Concrete is a heterogeneous material that is made by mixing cement, sand, coarse aggregates (CA), and water [1] Manufacturing sand (M−sand) was used as FA and sieve analysis was carried out in accordance with IS 383 Specification for Coarse and Fine Aggregates From Natural Sources for Concrete, Indian Stand (1970) 1–24 Google Usage potential and benefits of processed coconut shells in concrete

manufacturing sand and aggregates for concrete in india

Overview of Indian aggregate industry Indian Cement Review 2021年7月1日 Manufactured sand is one subset of aggregates Cement is used as a binder with aggregates