-

صفحة رئيسية > المنتجات >

dry mining processing plant

2021-05-09T01:05:20+00:00

Dry Mineral Processing SpringerLink

2022年2月28日 As a main part of the mining industry, ore processing plants are highly dependent on water, and water scarcity poses significant risk to the industry Thus, water consumption is a strategic issue for mineral processing plants, particularly in dry climate 2022年12月20日 Canadian Institute of Mining, Metallurgy and Petroleum Suite 1040, 3500 de Maisonneuve Blvd West Westmount, Quebec H3Z 3C1 CANADA Tel: (514) CIM Practice Guidelines for Mineral Processing2022年4月1日 The first comminution stage in a mineral processing plant is crushing, which reduces the size of particles from up to 1 m down to 05 cm (depending on the type of Review on advances in mineral processing technologies

Dry laboratories – Mapping the required instrumentation

2023年1月1日 Globally, the mining industry has been successful in discovering new mineral deposits, developing new methods of mining and processing ore This shows 2020年2月11日 Vale funds dry processing plant Vale plans to invest up to US$100 million on a new Fines Dry Magnetic Separation (FDMS) plant for lowgrade ironore processing Vale funds dry processing plant Mining Magazine2018年9月18日 The generation of iron ore fines in dry processing plant of Khondbond region, India is about 30–40% of the total feed The iron ore fine assayed 5873% Fe (T), Characterization and Beneficiation of Dry Iron Ore Processing Plant

Dry Mining Cornish China Clay AggNet

2008年6月2日 Dry mining process Designed to process several million tonnes of matrix a year from the Melbur and Virginia quarries, the new plant operates six days a week and 2022年9月1日 The shift of mineral processing operations from wet to dry or waterless media is key to mitigating the water stress of mining Dry separation technologies, Towards waterless operations from mine to mill ScienceDirect2019年9月1日 Abstract Water scarcity dictates to limit the use of water in ore processing plants particularly in arid regions Since wet grinding is the most common method for A comparative study on the effects of dry and wet grinding

Free FullText Gravity Concentration in Artisanal Gold Mining

2020年11月18日 Worldwide there are over 43 million artisanal miners in virtually all developing countries extracting at least 30 different minerals Gold, due to its increasing value, is the main mineral extracted by at least half of these miners The large majority use amalgamation either as the final process to extract gold from gravity concentrates or from 2023年11月7日 DOVE DESERTMINER ® plants, also known as Dry Processing plants, are mineral processing plants specifically designed by DOVE, with processing and recovery capabilities unmatched in the Dry Processing Plants For Alluvial And Hard Rock2019年9月1日 Water scarcity dictates to limit the use of water in ore processing plants particularly in arid regions Since wet grinding is the most common method for particle size reduction and mineral liberation, there is a lack of understanding about the effects of dry grinding on downstream separation processes such as flotationA comparative study on the effects of dry and wet grinding

Kaolinite Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 Kaolin dry beneficiation process The kaolinite dry mining process is a simple and economical process The ore is crushed to 254mm by a hammer crusher and fed into the cage mill to reduce the particle size to 635mm The hot air in the cage mill reduces the moisture of the kaolin from about 20% to 10%2022年5月1日 An intelligent dry fog system has been designed to suppress dust emission efficiently from mineral processing plants and opencast mines The developed system has special features for facilitating Intelligent dry fog dust suppression system: An2021年6月25日 Mining plays an essential role in resourcerich countries given that it constitutes a source of raw materials and incomes capable of contributing to the economic growth However, with the intensive mechanisation of mining operations and the modernisation of the oreprocessing technologies in view of increasing the Review of Practices in the Managements of Mineral Wastes

Characterization and Beneficiation of Dry Iron Ore Processing Plant

2018年9月18日 During dry processing of iron ore in Khondbond region of Orrisa, approximately 30–40% (by weight) of total feed is produced as fines These fines are being dumped and get accumulated at mine site as plant reject Accumulation of fines over the year poses significant environmental impact on land, water, and air2020年2月11日 Vale said the plant's capacity would be 15 million metric tonnes per year "With New Steel, Vale estimates that, in 2024, 70% of production will come from dry or natural moisture processing, without adding water to the process and without using tailings dams," the company saidVale funds dry processing plant Mining Magazine2018年2月14日 If you think the differences between dry and wet screen mining are limited to the presence or lack of water, then you're missing several important points First of all, wet separation technology requires additional equipment, including the spray nozzles that funnel the water Extra plant capital is on the agenda when these additional stages enterDry and Wet Screening in Mining: What are the Differences?

Mineral Processing SpringerLink

2017年8月24日 According to Wills and Finch , «ore handling is a key function in mining and mineral processing, which can account for 30–60% of the total delivered price of raw materials» It covers mainly the processes of transportation between the mine and the mineral processing plant and between the various stages of treatment in the plant2010年6月30日 This article provides a global view of the types of dewatering equipment and dryers currently used in the mineral processing industries, provides guidelines for selection of drying systems, and (PDF) Dewatering and Drying in Mineral 2019年7月8日 Graphical Abstract 1 Introduction Sensorbased ore sorting is gaining increased attention both within and outside the mining industry, as it is leaving the state of pilot plant scale and technology roadmapping, and an increasing amount of equipment is installed in highcapacity production scale environmentsSensorBased Ore Sorting Technology in Mining—Past,

Special Issue "Process Optimization in Mineral Processing"

2021年6月18日 The theme of the Special Issue is process optimization in mineral processing, a vitally important and comprehensive area of research Multidisciplinary collaboration is required, since production of saleable concentrate of high quality is the sum of many factors and requires wide understanding of the technical and economical 2022年8月14日 Mining and processing plant design ESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual technical solutions, etc • From €50 million and more • Investments up to 90% of the project cost • Loan term from 10 to 20 Mining and processing plant engineering design ESFC2019年5月1日 At Wonnerup, Tronox mines ore deposits using drymining techniques before running it through a concentrator to produce heavy mineral concentrate (HMC) HMC is transported by road to the Northshore Processing Plant Wonnerup Sues Road, Wonnerup 6280, Western Australia, Australia Northshore Lot 962 Koombana Drive Bunbury, 6230, Wonnerup/Northshore Tronox

(PDF) Methods for the disposal and storage of mine tailings

2007年7月1日 The degree of metal and metalloid process extraction depends upon the economic interplay between the extent of plant investment and efficiency and the price of the particular targeted metal or 2 天之前 These projects had 13 processing plants, predominantly for LNG exports and domestic gas sales The attached tables below provide details of the State’s principal mining projects, principal producers of basic raw materials, principal mineral processing operations, and petroleum projects PRINCIPAL MINING PROJECTS Company Project(s) CommentsWestern Australia’s principal resources projects, 2019202 天之前 The calcination process increases whiteness and hardness, improves electrical properties, and alters the size and shape of the kaolin particles Our dry mining processing plant in Cornwall, UK Panorama of our Melbur kaolin clay quarry, UK Kaolinite is a silicate clay mineral with the chemical composition Al 2 Si 2 O 5 (OH) 4 Physical Kaolin Imerys

New dry iron ore processing technology developed Australian Mining

2016年5月26日 New dry iron ore processing technology developed Ben Creagh May 26, 2016, 9:24 am The mine tailing dam spill at BHP and Vale’s Samarco iron ore operations last year killed 19 people and had 2023年5月3日 Mineral processing plant is a plant in which mineral processing is implemented to obtain concentrate products that are suitable for metallurgy or other industrial applications It is an indispensable intermediate production process between ore mining and smelting or chemical engineering The nonferrous metal minerals to be Mineral Processing Plant SpringerLinkAll processing activities can lose some of the desired mineral resources, which may occur at any processing stage, with some mining projects losing more than others In turn, to measure the amount of recovered mineral, a Mineral Processing Plants Multotec

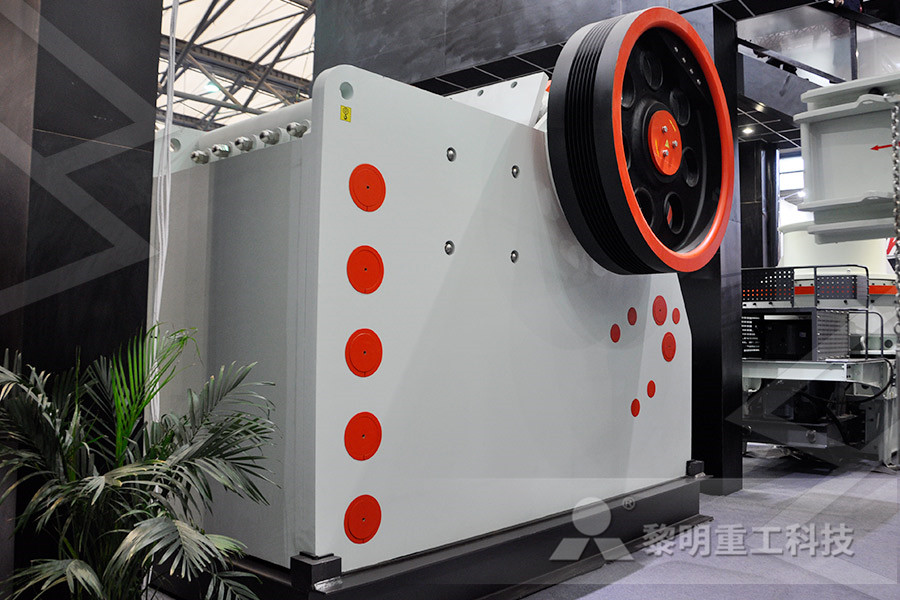

Review on advances in mineral processing technologies

2022年4月1日 The first comminution stage in a mineral processing plant is crushing, which reduces the size of particles from up to 1 m down to 05 cm (depending on the type of milling circuit) Crushing is typically a dry process that makes use of Gyratory, Jaw, and Cone crushers (NapierMunn et al, 1996), which predominantly make use of impact mechanism2023年10月25日 Dry Mining above water table – Two processes will be adopted for dry mining, Dry Mining with Excavator and FrontEnd Loader This method will be adopted in areas where there is no habitation and settlement After excavating mineral sands will be taken to the Wet Plant Dry Mining utilizing local equipment and local workforce – This Mining and Processing – Everlast Minerals2015年8月8日 The process can be carried out wet or dry Removal of the final product can be carried out using air (where the process is dry) removing only the fines This can provide a reduction in plant costs if a single mill is used as a substitute for two or more stages There is little wear as the grinding isMineral processing milling

Converting Tailings Dumps into Mineral Resources Deloitte

2016年12月6日 Several commercially profitable enterprises have also been set up with the sole intention of retreating tailings dumps arising from South Africa’s Witwatersrand gold processing operations According to Munyar Chirisa, a chemical engineer and senior manager of Deloitte, any tailings dump can be considered a potential mineral asset as Contribute to chengxinjia/ development by creating an account on GitHub/ drying machinery mining processingmd at main2015年9月10日 1121 Phosphate Rock Processing The rock is maintained at about 10 percent moisture and is stored in piles at the mine and/or chemical plant for future use The rock is slurried in water and wetground in ball mills or rod mills at the (Mg/hr) (250 tons per hour [ton/hr]) of rock will discharge between 31 and 45 dry normal cubic meters 1121 Phosphate Rock Processing US EPA

1125 Clay Processing US EPA

2015年9月10日 A process flow diagram for kaolin mining and dry processing is presented in Figure 11251, and Figure 11252 illustrates the wet processing of kaolin transported to the processing plant and stockpiled In some cases, the crude clay is weathered for 6 to 12 months, depending on the type of fire clay 2022年6月23日 Step 1: Separate the electrical appliances and the quick connections along the pipeline of each module of the mobile plant Step 2: Respectively adjust the idler wheel's height of each loading module Firstly rotating the lifting screw rod to make the distance A from the under the pan to the ground is 2cmUltimate Guide of Mobile Mineral Processing Plant Mining 2013年12月31日 Abstract Uranium is the primary fuel for nuclear power generation To a very much greater extent than for other fuels to produce electricity it must undergo processing both at the mine and (PDF) Uranium Mining, Processing, and Enrichment

Mineral Processing – Can We Keep It Dry? kuchling

2019年9月30日 Is dry grinding possible Wet grinding is currently the most common method for particle size reduction and mineral liberation However research is being done on the future application of dry grinding The current studies indicate that dry grinding consumes higher energy and produces wider particle size distributions than with wet grinding2023年2月26日 Innovation in mineral processing February 26, 2023 Jonathan Rowland Coarse particle flotation and bulk ore sorting are starting to make waves in the mineral processing industry North American Mining takes a look at both technologies with the help of experts from three leading mineral processing OEMs By Jonathan RowlandInnovation in mineral processing North American Mining2 天之前 Mineral processing is a form of extractive metallurgy that separates valuable minerals from the ore into a concentrated, marketable product Mineral processing is also known as mineral dressing Mineral processing is conducted at the site of the mine and is a highly mechanical process, with oversight from a central control room Why is Mineral What Is Mineral Processing in Mining? Flyability

Gold Mining Equipment Diamond Mining Equipment DOVE

2023年10月23日 DOVE is a major manufacturer of hard rock gold mining equipment, and hard rock mining equipment, and crushing plants for base metals, ferrous metals and light metals, producing Ball Mills, Jaw Crushers, Cone Crushers, Magnetic Separators, Shaking Tables, Gold Concentrators, Rotary Dryers, and Flotation Process SPEEDMINER ® 2017年3月3日 For example, one of such objects in minerals processing plants is the vibrating screen, Fig 1 Sieving is a process of separation of the ore material into multiple grades by particle size [1] (PDF) ORE SEPARATION BY SCREENING ResearchGate2016年11月1日 “ilmenite wet process” This dry mining operation was performed at an average rate was 700 tons per hour The dry mine approach with a dry separation and ore purification method resulted in a cost per ton that had the owners conclude that the mine was nearing the end of its economic life near the start of the new Millennium end of 1999 FROM HEAVY MINERALS MINING TO A WET DREDGE

Processing lowgrade coal to produce highgrade products

The challenge to the coal processing industry is to process lowyielding coals to produce goodquality products and at the same time ensure that coal mining remains economically viable This requires that more costeffective coal processing technologies be investigated and implemented Keywords: lowgrade raw coal, new developments, lowcost 2020年11月18日 Worldwide there are over 43 million artisanal miners in virtually all developing countries extracting at least 30 different minerals Gold, due to its increasing value, is the main mineral extracted by at least half of these miners The large majority use amalgamation either as the final process to extract gold from gravity concentrates or from Free FullText Gravity Concentration in Artisanal Gold Mining 2023年11月7日 DOVE DESERTMINER ® plants, also known as Dry Processing plants, are mineral processing plants specifically designed by DOVE, with processing and recovery capabilities unmatched in the Dry Processing Plants For Alluvial And Hard Rock

A comparative study on the effects of dry and wet grinding

2019年9月1日 Water scarcity dictates to limit the use of water in ore processing plants particularly in arid regions Since wet grinding is the most common method for particle size reduction and mineral liberation, there is a lack of understanding about the effects of dry grinding on downstream separation processes such as flotation2019年8月23日 Kaolin dry beneficiation process The kaolinite dry mining process is a simple and economical process The ore is crushed to 254mm by a hammer crusher and fed into the cage mill to reduce the particle size to 635mm The hot air in the cage mill reduces the moisture of the kaolin from about 20% to 10%Kaolinite Processing Equipment, Process Flow, Cases JXSC 2022年5月1日 An intelligent dry fog system has been designed to suppress dust emission efficiently from mineral processing plants and opencast mines The developed system has special features for facilitating Intelligent dry fog dust suppression system: An

Review of Practices in the Managements of Mineral Wastes

2021年6月25日 Mining plays an essential role in resourcerich countries given that it constitutes a source of raw materials and incomes capable of contributing to the economic growth However, with the intensive mechanisation of mining operations and the modernisation of the oreprocessing technologies in view of increasing the 2018年9月18日 During dry processing of iron ore in Khondbond region of Orrisa, approximately 30–40% (by weight) of total feed is produced as fines These fines are being dumped and get accumulated at mine site as plant reject Accumulation of fines over the year poses significant environmental impact on land, water, and airCharacterization and Beneficiation of Dry Iron Ore Processing Plant 2020年2月11日 Vale said the plant's capacity would be 15 million metric tonnes per year "With New Steel, Vale estimates that, in 2024, 70% of production will come from dry or natural moisture processing, without adding water to the process and without using tailings dams," the company saidVale funds dry processing plant Mining Magazine

Dry and Wet Screening in Mining: What are the Differences?

2018年2月14日 If you think the differences between dry and wet screen mining are limited to the presence or lack of water, then you're missing several important points First of all, wet separation technology requires additional equipment, including the spray nozzles that funnel the water Extra plant capital is on the agenda when these additional stages enter

dry mining processing plant

Dry Mineral Processing SpringerLink 2022年2月28日 As a main part of the mining industry, ore processing plants are highly dependent on water, and water scarcity