-

صفحة رئيسية > المنتجات >

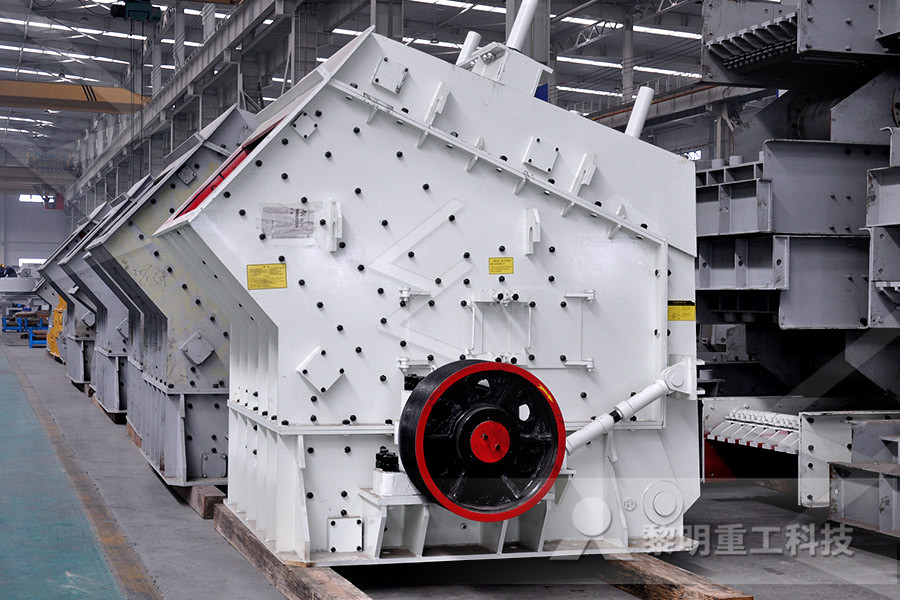

impact crusher grains

2021-06-17T14:06:57+00:00

Constructive and regime parameters of horizontal impact crusher

2019年12月1日 Nowadays, impact and centrifugalrotor grain crushers that use a “slicechipping” are the most effective ones The smallsized horizontal impact crusher, which constructive and technological scheme of grinding is fixed in the patents of the Russian Impact crushers provide better grainsize distribution of RA for road construction purposes, and they are less sensitive to material that cannot be crushed, such as steel Impact Crusher an overview ScienceDirect Topics2019年12月19日 The conducted multifactorial experiment showed that the proposed design of the impact crusher allows obtaining up to 98% of the finished product balanced Constructive and regime parameters of horizontal impact crusher

Impact crushers and impact mills with a horizontal shaft for

The impact crusher can be repurposed into an impact mill for manufacturing fine grains by inserting a higher machine base and an additional grinding track This flexible solution 2022年12月27日 The article presents the parameters used to evaluate the efficiency of the crusher, productivity and specific work for grinding grain Methodology for conducting Evaluation of the efficiency of the impact crusher in order to 2021年5月17日 The crushing process relates to the types of crushers used in each quarry (Fig 1): cone crusher (C), impact crusher (I), quarry jaw crusher (QJ), and laboratory jaw The influence of crushing processes and mineralogy of aggregates

Evaluation of the efficiency of the impact crusher in order to

2022年12月27日 A scientific and technical literature review on machines designed to grind fodder grain revealed that the existing designs of grinding machines—those based on 2020年10月31日 The greatest impact on crusher productivity is exerted by the diameter of the sieve holes and the area of the bunker’s unloading window The greatest effect on the specific energy intensity of(PDF) Studying the operational efficiency of the Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes As the name suggests, an impact crusher accelerates the feed Impact crushers highquality impactors

Minerals Free FullText Milling Studies in an Impact Crusher

2021年3月20日 A number of experiments were conducted on a laboratory batch impact crusher to investigate the effects of particle size and impeller speed on grinding rate and There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefitsTypes of Crushers: What You Need to Know Machinery 2021年11月12日 The Discrete element method (DEM) is an invaluable tool for studying comminution as it provides detailed information that can help with process analysis as well as trying out new equipment designs Numerical Simulation of a Single and Double

Impact crusher structure, working principle and

2021年9月2日 11 Impact crushers can be divided into two types according to the number of rotors: singlerotor and doublerotor impact crushers 12 The structure of the single rotor impact crusher (Figure 1) is relatively 2021年12月3日 impact of energy per unit mass in VSItype crusher is greater than those of HSItype crusher Rahimdel and Ataei (2014 ) employed an analytical hierarchy pro cess (AHP) to select primary crushi ng (PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY2023年11月4日 Required feed size for the cone crusher In selected example: UD: Slotted grate, AGW 2 1/2” LD: Wire cloth, CMS 22 mm; 7/8” Prescreen: Not required if primary screening of upstream jaw crusher is active The No4 content of fi nes produced by the jaw crusher are tolerated by the cone crusher Jaw crusher: Adjustment of the jaw crusher, seePrimary and secondary raw materials

Technical Information MOBIREX MR 130(i) PRO

2023年2月8日 Crusher Impact crusher type SHB 130 090 Crusher inlet width x height (mm) 1,300 x 900 Crusher weight approx (kg) 17,500 Rotor diameter (mm) 1,200 Crusher drive type, approx (kW) electric, 250 Adjustment of impact toggles infinitely variable, fully hydraulic Discharge chute Width x Length (mm) 1,435 x 2,670 Crusher discharge conveyorCompound impact crusher In the compound impact crusher the two stages – primary and secondary – are combined in a single machine this is a dual – rotor crusher in which the primary rotor runs at 35 m/ second and the secondary rotor (mounted below and to one side of the primary) runs at about 45m/ second circumferential velocityEverything you need to know about Crushers in Cement 2022年9月22日 grain returning (option) OPERATING POSITION 21,400 mm 4,800 mm 4,350 mm 3700 mm 3,650 mm TECHNICAL HIGHLIGHTS Feeding unit Feed capacity up to approx (t/h)1) 450 Crusher Impact crusher type SHB 130 090 Crusher inlet width x height (mm) 1,300 x 900 Crusher weight approx (kg) 16,500MOBIREX MR 130(i) EVO2 Wirtgen Group

Impact vs cone crushers: Which is more effective? Quarry

2015年4月1日 The postprimary crushing sector is largely divided into impact crushers for the processing of softer stone and cone crushers for the processing of harder, more abrasive stone The advantages of both machines are well known The impact crusher, for example, has a higher coefficient of reduction, produces crushed material with an optimal cubic 2022年6月16日 grain developed and manufactured 100% inhouse The physical properties of our neoX® grains are particularly suited for high abrasion and high impact applications, where standard ceramic grains do not yield suffi cient performance gainsIMPACT CRUSHER WEAR PARTS OPTIMIZED CRUSHER 2011年5月10日 An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

Crushing technology Technologies Wirtgen

2023年11月5日 With the cone crushers used by KLEEMANN, the crusher shaft is pressfitted into the main frame The crusher cone carrier is mounted on an eccentric power supply unit The rotation of the power supply unit opens the gap in a circulating movement between crusher cone and bowl liner Raising and lowering of the bowl liner changes the grain 2023年2月15日 Impact crusher: Although the grain shape is more rounded after 23 shaping processes, multiple impacts seriously affect the output (productivity) Hammer crusher: It has a higher output, up to 3 times that of an impact crusher Therefore, it is often used in largescale and highyield production lines 6 Different in grain shapeImpact Crusher Vs Hammer Crusher: 8 Key Differences2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several Evaluation of size reduction process for rock aggregates in cone crusher

Roller crushers in iron mining, how does the degradation of

2021年4月1日 Whilst crusher feeding, iron ore fragments strike the crusher segments surface under higher pressure, and thus form impact deformation marks at different scales (macro and micro) caused by its morphology (circularity and roundness) and fragment size (good examples for macro and micro scales impact marks are shown in Fig 16 and Fig The mobile impact crusher MOBIREX MR 130 EVO2 can be deployed universally as an allrounder and produces first class final product quality With a crusher inlet width of 1300 mm, it achieves a production rate that until now was only associated with considerably larger crushing plant This is made possible by outstanding cost effectiveness and MR 130 EVO2 Mobile impact crushers Wirtgen 2023年5月12日 The grain shape of the sand is not as good as the sand produced by the HVI sand crusher HVI sand making machine HVI sand making machines is also called a highefficiency vertical shaft impact crusher Its crushing chamber adopts the best material impact angle design, achieving sand making and shaping6 Sand Making Machines and How to Choose the Best One

Materials Free FullText Influence of Basalt Aggregate

2023年1月8日 The feed for crushing was designed based on the original geometric grain composition and the separated feed in the form of flaky and nonflaky particles The crushability test results demonstrated that the interparticle compression in the jaw crusher resulted in finer products compared to the one in the cone crusher2022年9月22日 The MOBIREX MR 110(i) EVO2 mobile impact crusher can be deployed universally and produces firstclass final product quality With a crusher inlet of 1,100 mm and numerous tech > Belt scale, available for crusher discharge conveyor, medium grain conveyor and fine grain conveyor (post screening unit)Technical Information MOBIREX MR 110(i) EVO22018年11月19日 well into very small particles or in midsize grain [14] (Wills, 2006) Impact crusher uses unique technic as its name suggests: impaction Without any pressure, attrition (PDF) Comminution in mineral processing ResearchGate

Impact crushers highquality impactors

Impact crushers produce highquality end products efficiently Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fastmoving rocks against the walls of the crushing chamber and each 2021年11月9日 The highspeed impact crusher works on the impact breaking principle, ie, a device with a hammer Grain Size: One of the most important factors when choosing a granite crusher is grain shape It will affect how much material enters into cracks and reduce the production cost Still, suppose you want to produce finished products with needles Types Of Crusher Advantages and DisadvantagesThe mobile impact crusher MOBIREX MR 110i EVO2 can be deployed universally and produces first class final product quality With a crusher inlet of 1100 mm and numerous technical highlights, a formidable production rate can be achieved with best cost effectiveness Thanks to its compact design, the machine is easy to transport and can be MR 110i EVO2 Mobile impact crushers

(PDF) Influence of Natural Aggregate Crushing Process on Crushing

2021年7月27日 The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type Aggregate crushing was carried out in a Los Angeles drum, in accordance The impact crusher can be repurposed into an impact mill for manufacturing fine grains by inserting a higher machine base and an additional grinding track This flexible solution allows you to benefit from excellent crushing results and respond to changing project requirements at any time Impact crushers are traditionally used for rock Impact crushers and impact mills with a horizontal shaft for2020年2月10日 The crusher machines of the crushing step may employ use jaw crusher, impact crusher, cone crushing, hammer crusher, sand maker The artificial sand size different, the crushing equipment is different Manufactured sand can be manufactured to be a certain grain size that the buyer chooses, while natural sand can be a mix of coarse Artificial Sand Manufacturing Process Eastman Rock Crusher

Impact crusher Eureka Patsnap

A technology of impact crusher and crushing cavity, applied in grain processing and other directions, can solve the problems of poor product particle size uniformity, affecting the quality of material processing, and not suitable for largescale processing of materials, so as to accelerate the crushing efficiency and improve the quality Effect2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap How it Works: Crushers, Grinding Mills and Pulverizers1000g Swing Type Electric Grains Herbal Powder Miller Dry Food Grinder Machine High Speed Intelligent Spices Cereals Crusher US$ 68 / PieceChina Dry Food Crusher, Dry Food Crusher Manufacturers,

Grain crushing in geoscience materials–Key issues on

2020年3月1日 Moreover, the grain number in the Xray microtomography for tracing the grain crushing and grain movement is limited, although this method has been also used to observe the whole process of grain crushing during compression and shearing (Cil and Alshibli, 2012, Alam et al, 2018, Hurley et al, 2018, Karatza et al, 2019)Contribute to naicha22/2022 development by creating an account on GitHub2022/ what 39 s grain crushermd at main naicha22/年2月12日 2) With final grain size 0“ 18“ with approx 1015 % oversize grain 3) With final grain size 0“ 13“ with approx 1015 % oversize grain 4) All electric ancillary drives MOBIREX MR 110i EVO2 TECHNICAL DATA /TECHNICAL DRAWINGS KLEEMANN MOBIREX MR 110i EVO2 mobile impact crusher The MOBIREX MR 110i EVO2 mobile Technical Information MOBIREX MR 110i EVO2

(PDF) Influence of crusher type in the shape of fine

2018年8月1日 In uence of crusher type in the shape of ne crushed aggregate grains 322 Evaluation of the shape with the dynamic analyzer of particles for the material below the 015 mm sieve2019年12月10日 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor Impact crushers are suitable for materials that are soft or easily cleaving from the surface The crusher consists of a fast spinning rotor and beaters attached to the rotor The feed is entering to the crusher from the top and crushing starts Type of crushers and their difference JXSC Mining2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS

MOBILE PROCESSING Wirtgen Group

2023年11月4日 crusher is active The 05 mm content of fines produced by the jaw crusher are tolerated by the cone crusher Jaw crusher: Adjustment of the jaw crusher, see page 181, select acc to chap “Setting up jaw crusher”, depending on Desired intermediate product Required performance of secondary crusher Required feed size for the cone The invention discloses an impact crusher which comprises a frame (1) The frame (1) is equipped with a rotor (2), an arced front impact plate (3), and a back impact plate inside The rotor (2) is equipped with board hammer installing ports (5); the board hammer installing ports (5) are equipped with board hammers (6), and one side of each board hammer CNA Impact crusher Google PatentsHorizontal impact crusher: Primary/secondary: 1300: 200–300: Up to 1800: Cone crusher: Secondary The final grain size distribution is influenced by both the adjustable crusher setting and the suitability of the tooth form selected for the crushing plates Thus, the crusher jaws must be hard and tough enough to crush rock and meet the Crusher an overview ScienceDirect Topics

Buyer's Guide: Crushers Equipment Contracting

Impact Crushers An impact crusher (also called a hammer crusher) is quite versatile It can be used as a primary, secondary, or tertiary crusher Impact plates and beaters – or hammers – are used to break down the material The material is fed through the upper part of the crusher then hit by hammers Next, the pieces are thrown toward the Impact Grains (4078 products available) 1/6 high capacity stainless steel grain wheat corn feed hammer mill crusher machine impact hammer mill shredder machine for sale Ready to Ship $3,00000 / set 1 set (Min Order) $000Shop Now And Bag A Wholesale impact grains For LessThere are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefitsTypes of Crushers: What You Need to Know Machinery

Numerical Simulation of a Single and Double

2021年11月12日 The Discrete element method (DEM) is an invaluable tool for studying comminution as it provides detailed information that can help with process analysis as well as trying out new equipment designs 2021年9月2日 11 Impact crushers can be divided into two types according to the number of rotors: singlerotor and doublerotor impact crushers 12 The structure of the single rotor impact crusher (Figure 1) is relatively Impact crusher structure, working principle and 2021年12月3日 impact of energy per unit mass in VSItype crusher is greater than those of HSItype crusher Rahimdel and Ataei (2014 ) employed an analytical hierarchy pro cess (AHP) to select primary crushi ng (PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

Primary and secondary raw materials

2023年11月4日 Required feed size for the cone crusher In selected example: UD: Slotted grate, AGW 2 1/2” LD: Wire cloth, CMS 22 mm; 7/8” Prescreen: Not required if primary screening of upstream jaw crusher is active The No4 content of fi nes produced by the jaw crusher are tolerated by the cone crusher Jaw crusher: Adjustment of the jaw crusher, see2023年2月8日 Crusher Impact crusher type SHB 130 090 Crusher inlet width x height (mm) 1,300 x 900 Crusher weight approx (kg) 17,500 Rotor diameter (mm) 1,200 Crusher drive type, approx (kW) electric, 250 Adjustment of impact toggles infinitely variable, fully hydraulic Discharge chute Width x Length (mm) 1,435 x 2,670 Crusher discharge conveyorTechnical Information MOBIREX MR 130(i) PROCompound impact crusher In the compound impact crusher the two stages – primary and secondary – are combined in a single machine this is a dual – rotor crusher in which the primary rotor runs at 35 m/ second and the secondary rotor (mounted below and to one side of the primary) runs at about 45m/ second circumferential velocityEverything you need to know about Crushers in Cement

MOBIREX MR 130(i) EVO2 Wirtgen Group

2022年9月22日 grain returning (option) OPERATING POSITION 21,400 mm 4,800 mm 4,350 mm 3700 mm 3,650 mm TECHNICAL HIGHLIGHTS Feeding unit Feed capacity up to approx (t/h)1) 450 Crusher Impact crusher type SHB 130 090 Crusher inlet width x height (mm) 1,300 x 900 Crusher weight approx (kg) 16,年4月1日 The postprimary crushing sector is largely divided into impact crushers for the processing of softer stone and cone crushers for the processing of harder, more abrasive stone The advantages of both machines are well known The impact crusher, for example, has a higher coefficient of reduction, produces crushed material with an optimal cubic Impact vs cone crushers: Which is more effective? Quarry2022年6月16日 grain developed and manufactured 100% inhouse The physical properties of our neoX® grains are particularly suited for high abrasion and high impact applications, where standard ceramic grains do not yield suffi cient performance gainsIMPACT CRUSHER WEAR PARTS OPTIMIZED CRUSHER

impact crusher grains

Constructive and regime parameters of horizontal impact crusher 2019年12月1日 Nowadays, impact and centrifugalrotor grain crushers that use a “slicechipping” ar